News

-

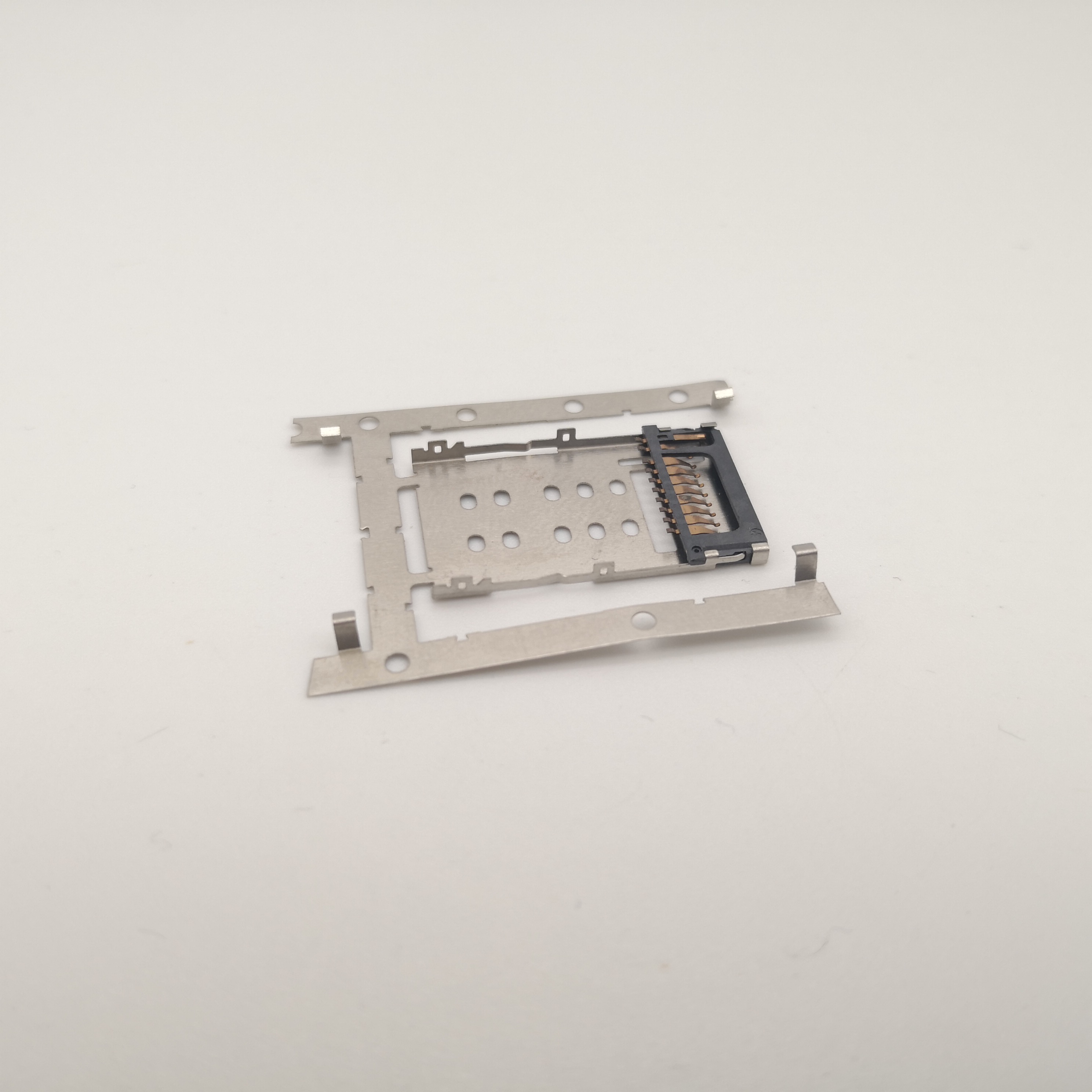

The 4 zones of metal stamping section and their characteristics

Metal stamping parts are very much used. In the stamping process of metal parts, after the ordinary punching process is completed, due to the influence of punching clearance and assembly clearance, it is inevitable that the upper surface of the product will collapse natu...Read more -

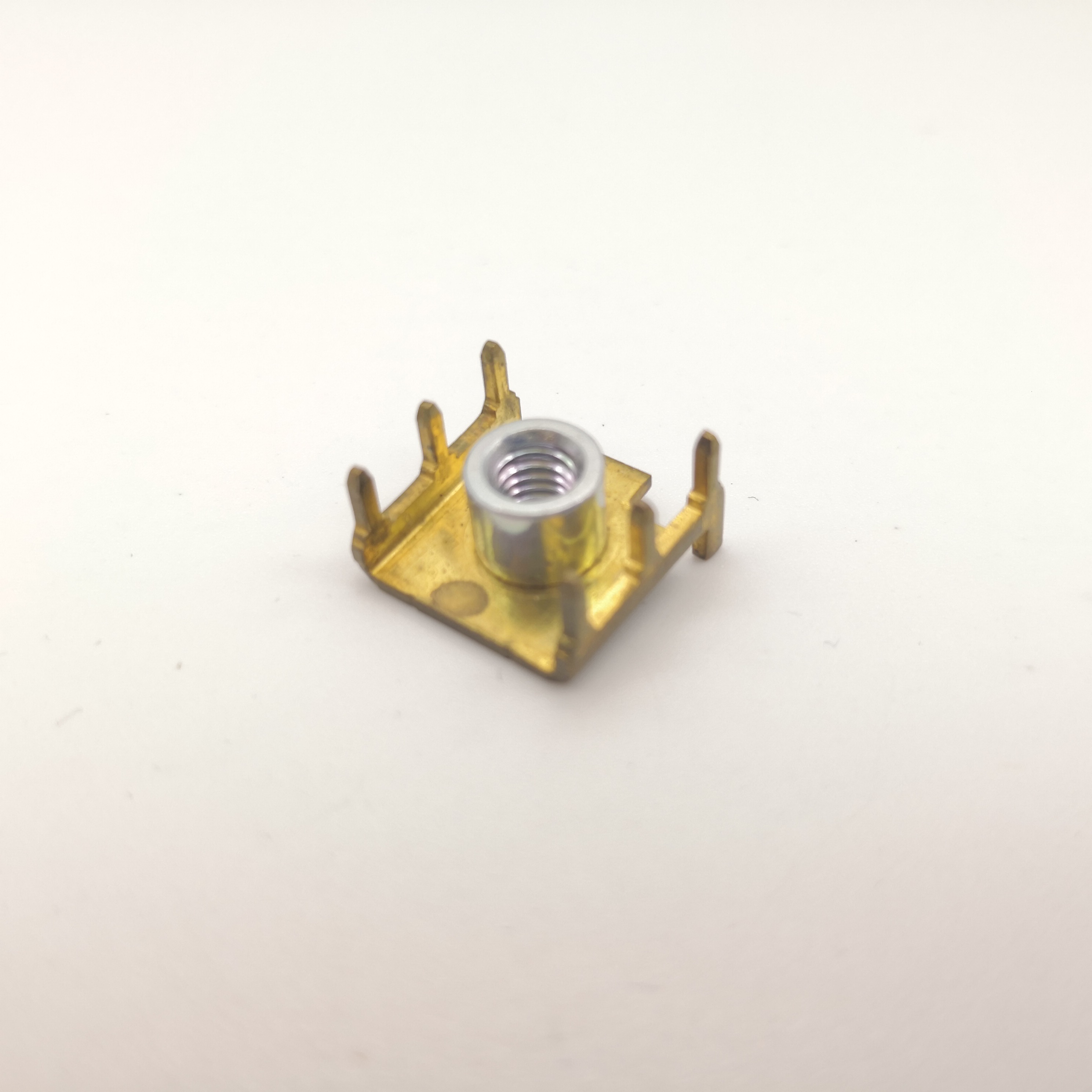

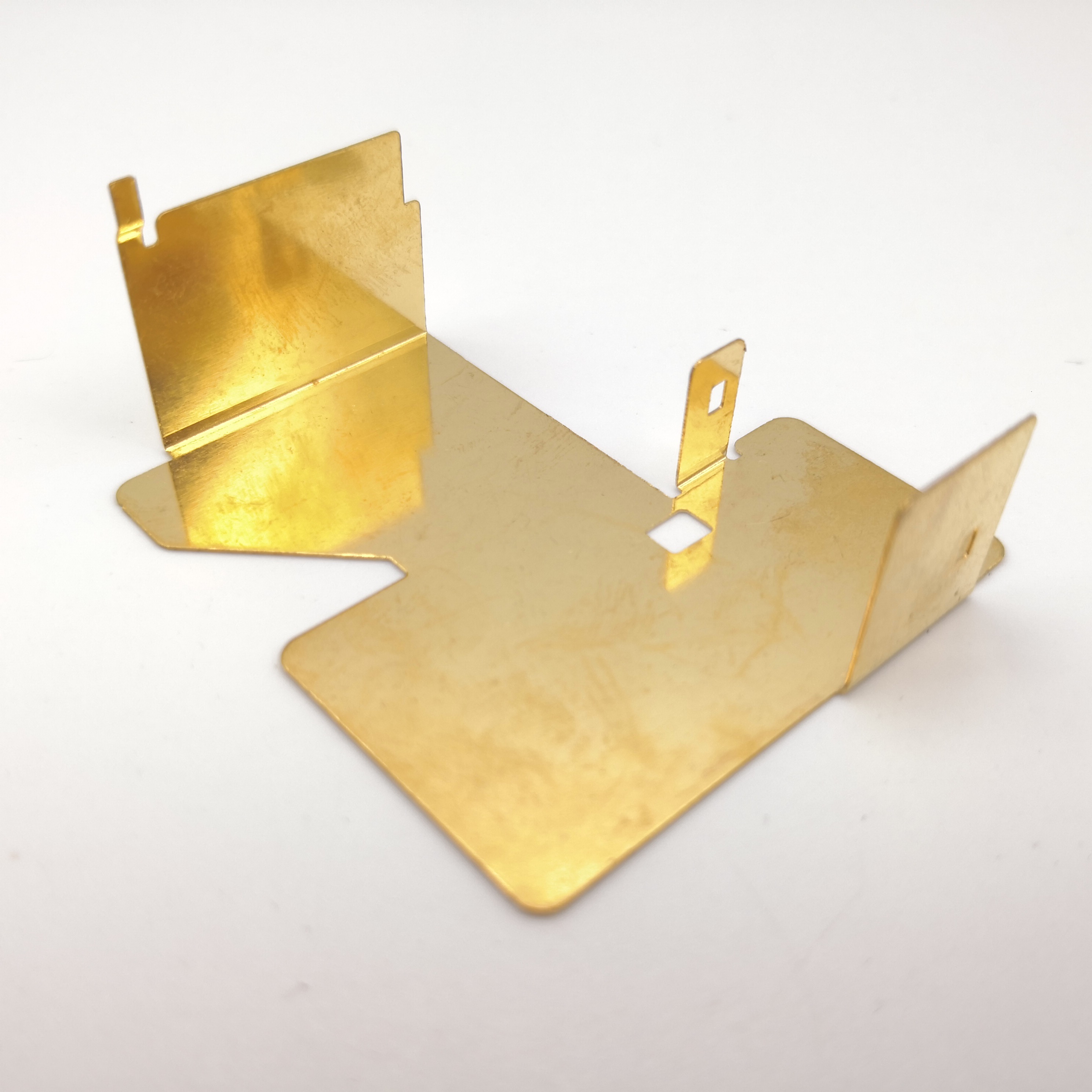

Introduction of three important methods for surface treatment

Raisingelec can provide all kinds of fasteners. The surface treatment of fasteners refers to the process of forming a covering layer on the surface of fasteners by certain methods. After the fasteners are surface-treated, they can show a more beautiful appearance, and the fasteners themselves are...Read more -

Common defects of forgings after heat treatment

Raisingelec can make any metal products.In the heat treatment of forgings, it is necessary to meet the performance requirements of the parts in the process of use, otherwise there will be many defects, so that the forgings cannot be used normally. In order to better understand the use of forgings...Read more -

Three major surface treatment technologies for hardware

Raisingelec can provide all kinds of screw products.Although the size of the screw is small, the function is not small, and the scope of application is also very wide, but many manufacturers still pay more attention to the use of the screw. Among them, the surface treatment technology is the most...Read more -

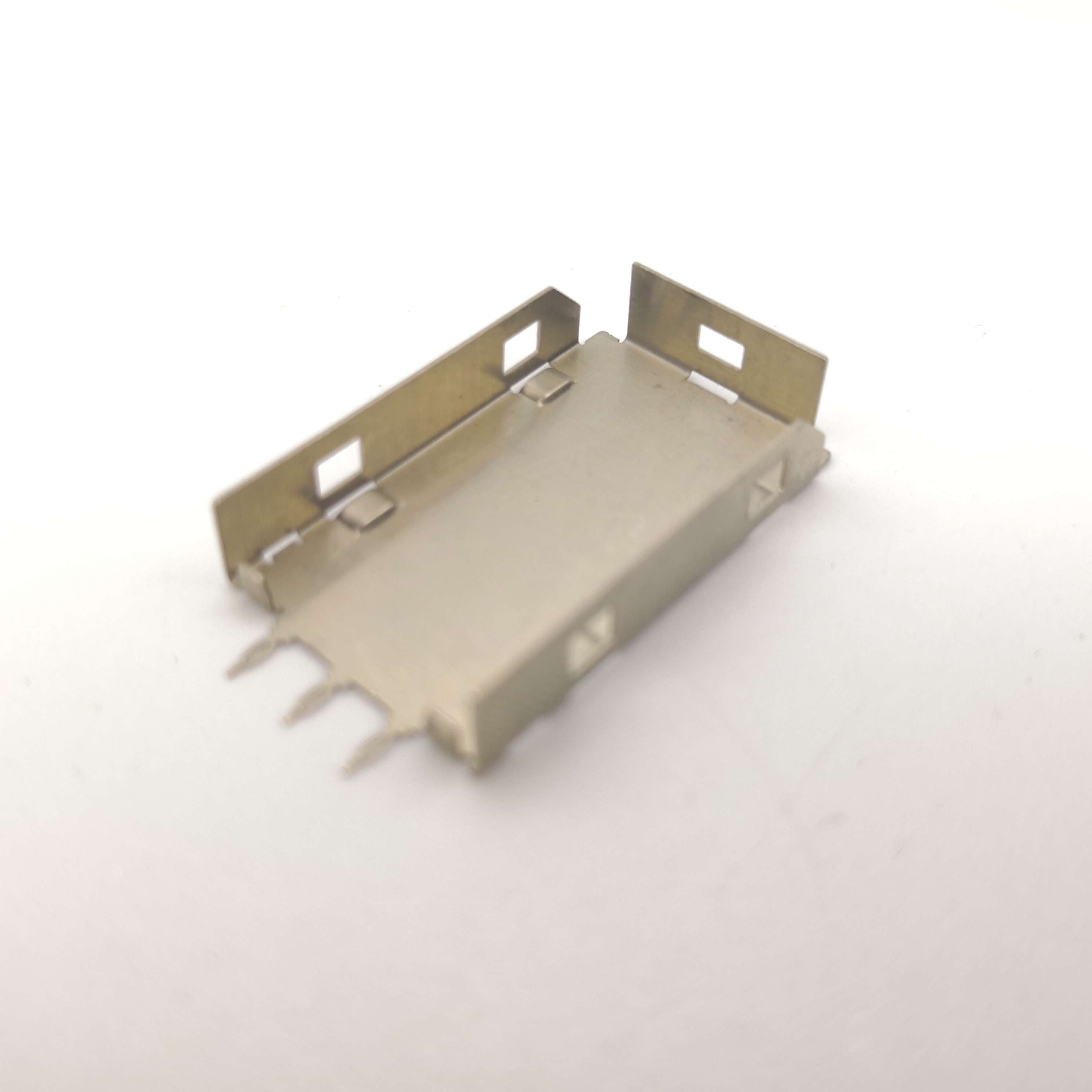

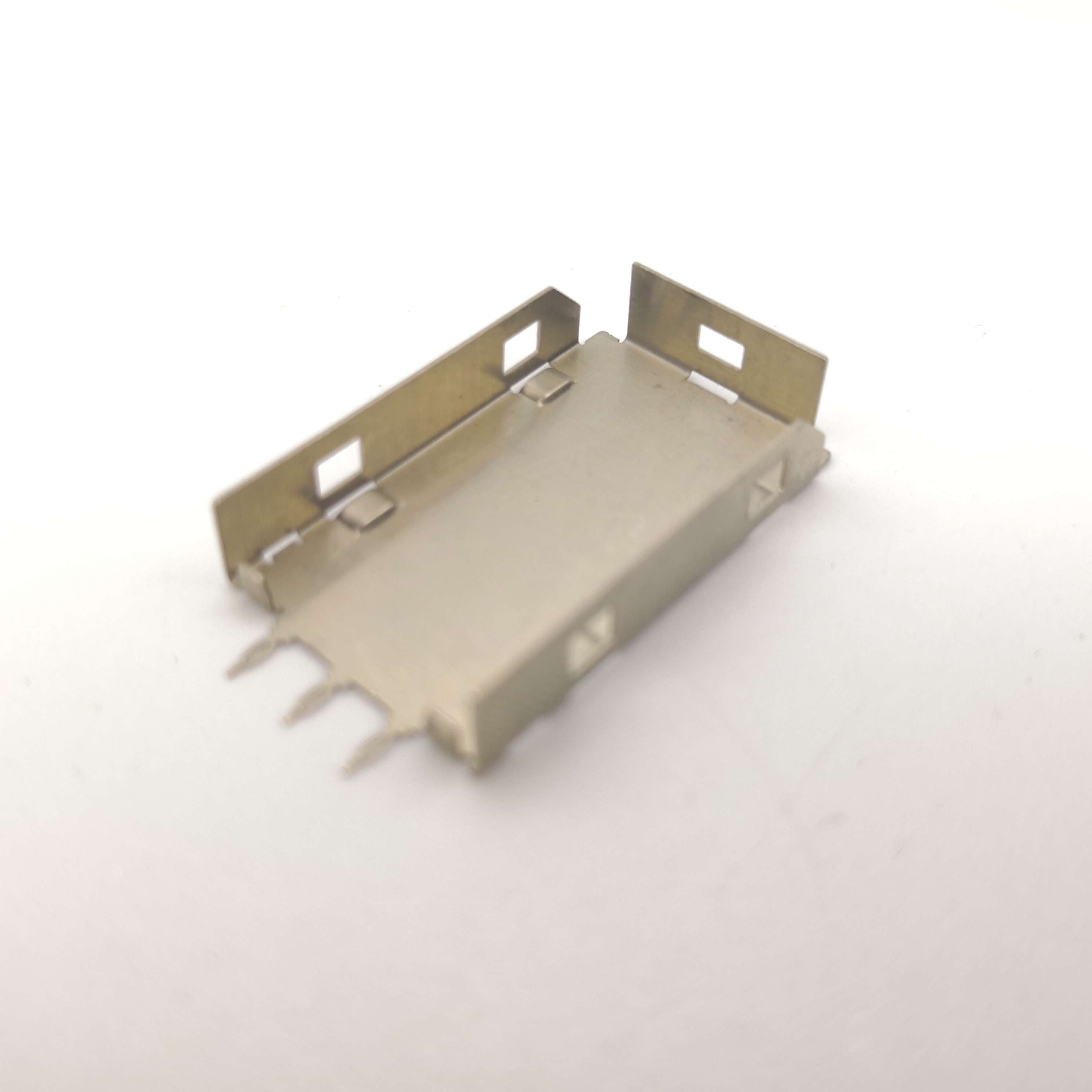

What are metal stamping parts?

The hardness test of metal stamping parts adopts hardness tester. Small, complex-shaped stampings can be used to test small planes that cannot be tested on ordinary benchtop hardness testers. The PHP series of portable surface Rockwell hardness testers are ideal for testing the hardness of these...Read more -

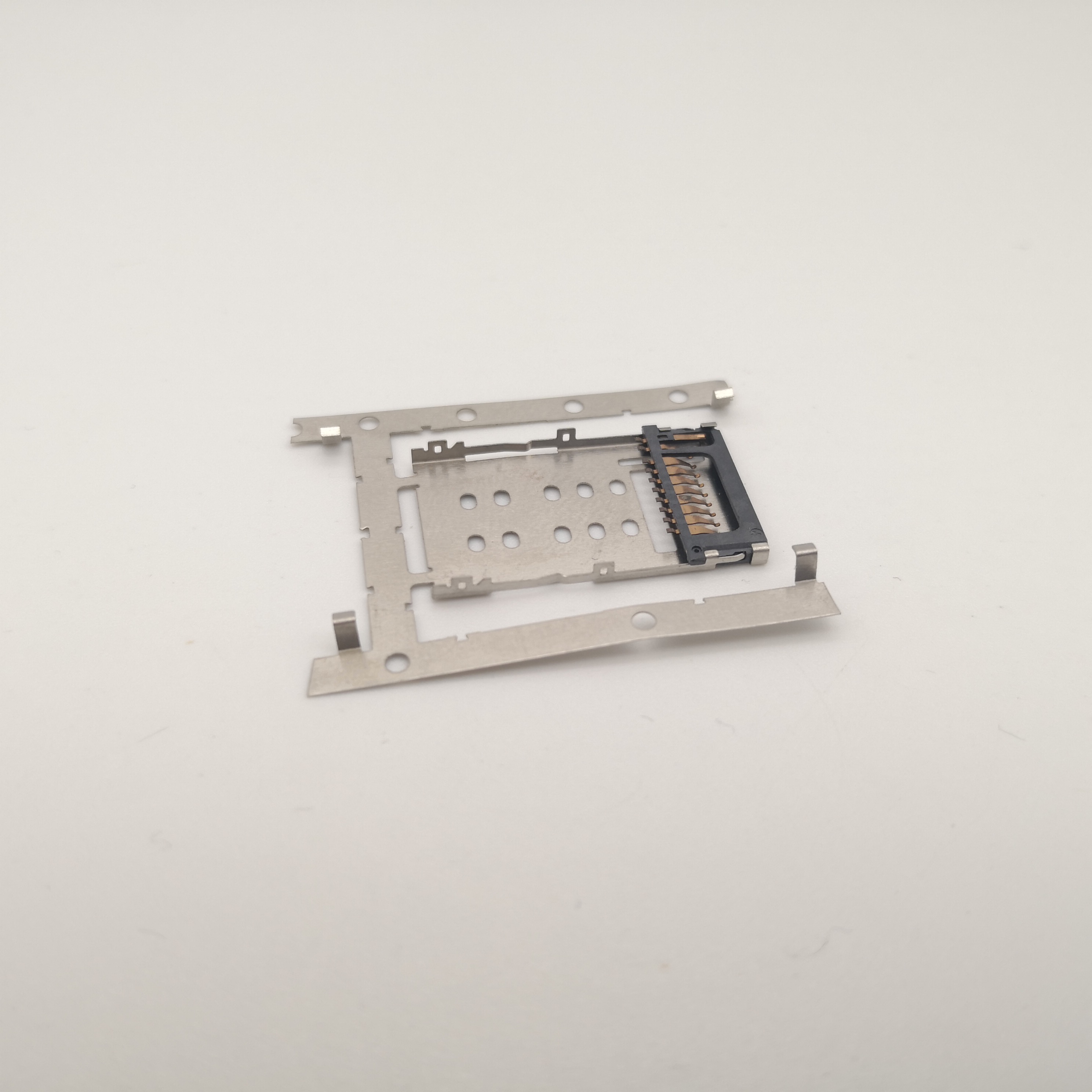

Introduction of stamping process characteristics

Stamping parts are sheet metal parts, that is, parts that can be processed by means of stamping, bending, stretching, etc. A general definition is – parts with constant thickness during processing. Correspondingly, castings, forgings, machined parts, etc. For example, the outer iron shell o...Read more -

What to pay attention to when opening stainless steel molds

Raisingelec specializes in mold manufacture, punching, etc. The mold needs to be opened before punching. The quality of the mold affects the quality and production efficiency of the mesh. Next, let’s see what to look out for when opening a good mold. First,pay attention to the choice of die...Read more -

The latest technology in stamping processing

Composite Process of Stamping and Electromagnetic Forming Electromagnetic forming is high-speed forming, and high-speed forming can not only expand the forming range of aluminum alloys, but also improve its formability. The specific method of forming aluminum alloy covers by composite stamping is...Read more -

Stamping design principles and advantages

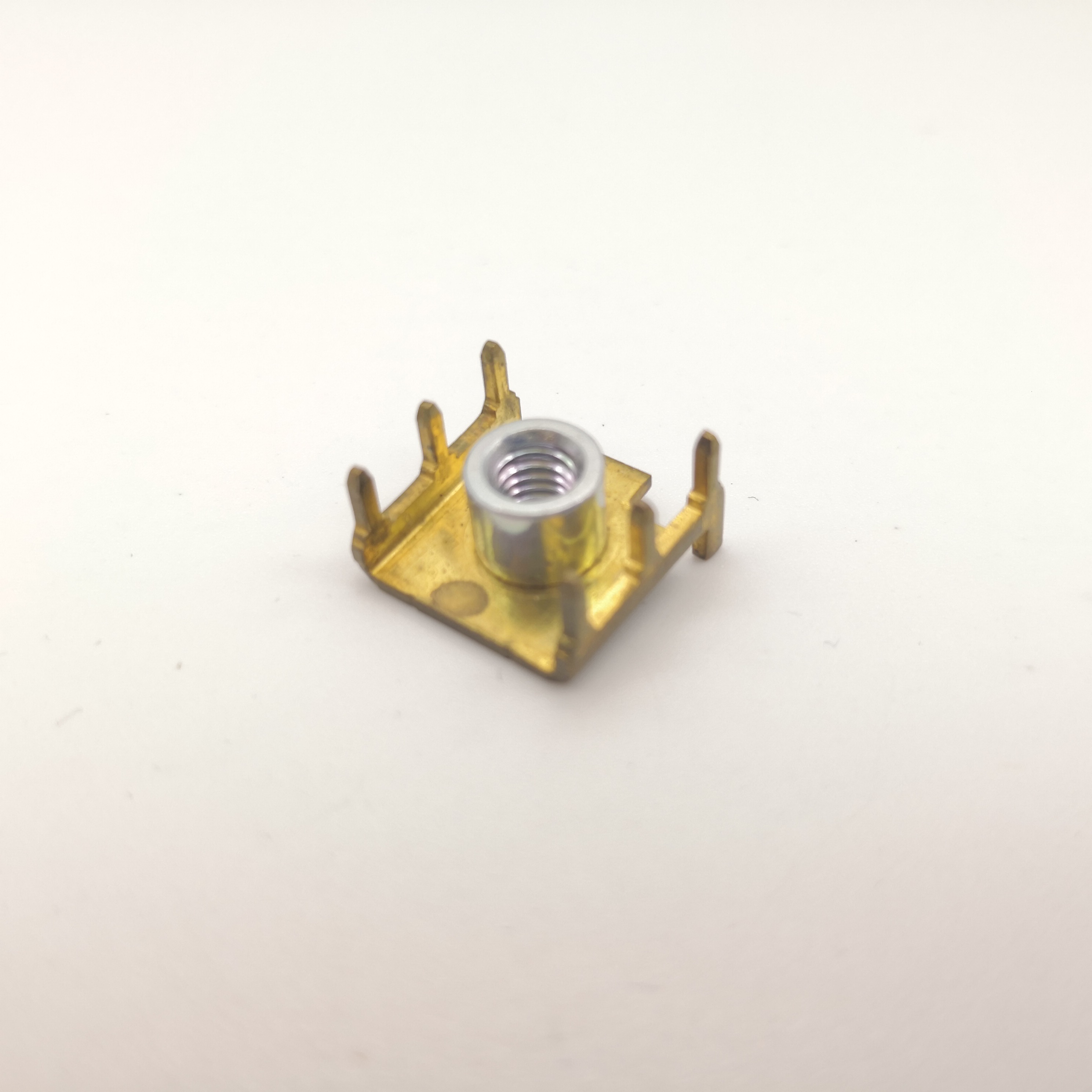

Design Principles for stamping parts in Raisingelec: (1) The stamping parts designed by Raisingelec must meet the product use and technical performance, and be easy to assemble and repair. (2) The stamping parts designed must be simple in shape and reasonable in structure, so as to simplify the ...Read more -

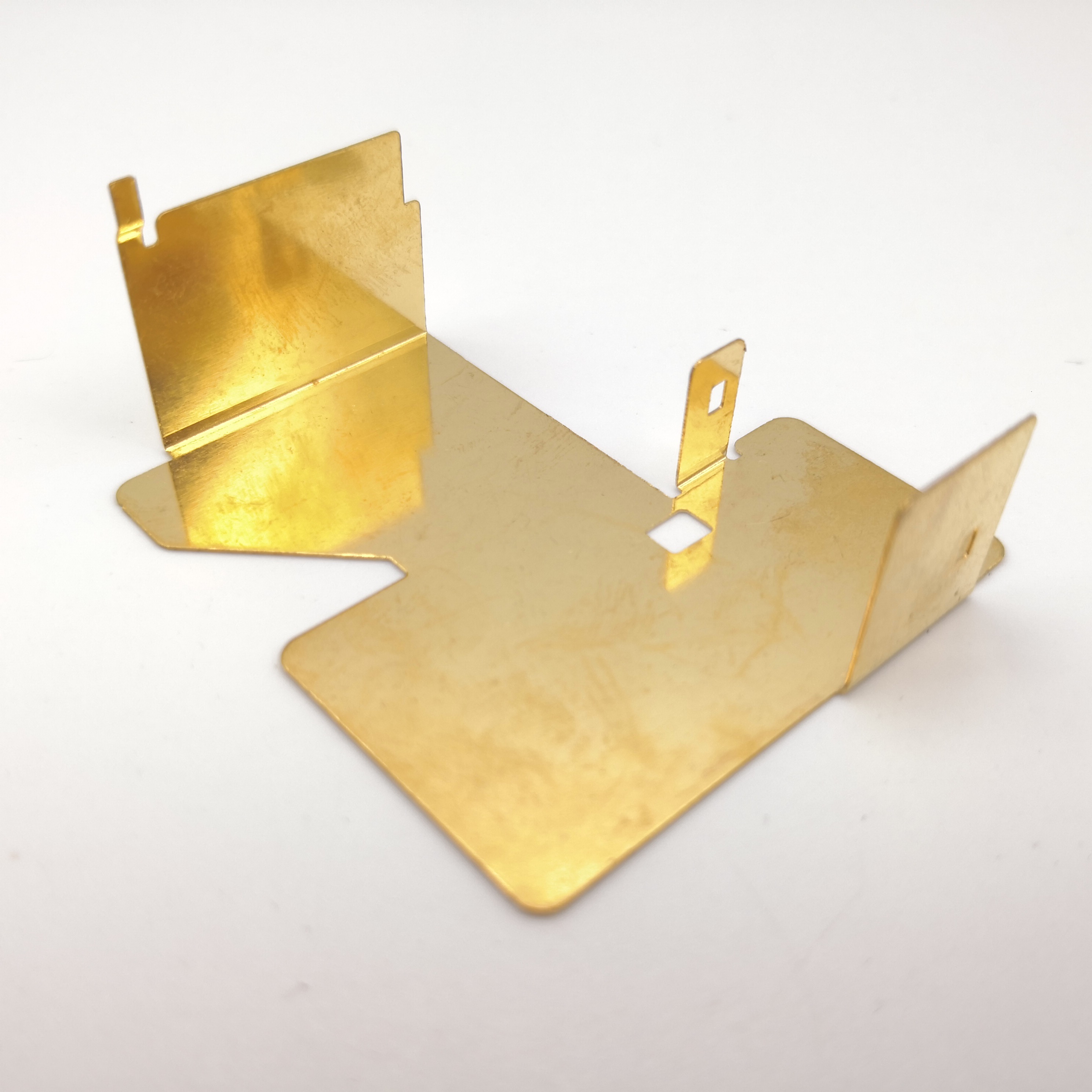

The role of stamping shrapnel

Due to its characteristics, springs are widely used in machinery and equipment manufacturing, electronics, electrical appliances, computers, high-tech product parts, etching, auto parts, kitchen supplies, adjusting gaskets, stainless steel foil molds and other industries. What is the function of ...Read more -

Function explanation of hardware spring

Metal spring is also known as metal spring. It is a mechanical part that uses elasticity to work. and has various functions. Squeeze function Observing various electrical switches, you will find that one of the two contacts of the switch must be equipped with a spring to ensure that the two conta...Read more -

The characteristics of precision mechanical parts

With the development of aerospace, industrial defense, industrial microelectronics, bioengineering and modern medical technology. The demand for high-precision and ultra-precision mechanical parts is increasingly urgent. Analysis of the high-precision mechanical parts processing industry: 1. The ...Read more