Wholesale Mold Die Supplier – Supporting services for die casting – RAISING-Elec

Wholesale Mold Die Supplier – Supporting services for die casting – RAISING-Elec Detail:

The advantages of die casting include excellent dimensional accuracy. Usually, this depends on the casting material. The typical value is that the error is 0.1mm for the first 2.5cm size, and the error increases by 0.002 mm for each additional 1cm. Compared with other casting processes, its casting surface is smooth, and the fillet radius is about 1-2.5 microns. Castings with a wall thickness of about 0.75 mm can be manufactured relative to sandbox or permanent die casting.

It can directly cast internal structures, such as wire sleeves, heating elements and high-strength bearing surfaces. Other advantages include its ability to reduce or avoid secondary machining, high production speed, casting tensile strength up to 415 MPa, and high fluidity metal casting.

The biggest disadvantage of die casting is the high cost. Casting equipment, molds and mold related components are expensive compared with other casting methods. Therefore, it is more economical to produce a large number of products when manufacturing die castings. Other disadvantages include: this process is only applicable to metals with high fluidity, and the casting mass must be between 30g and 10kg [5] 。 In normal die casting, the last batch of castings will always have pores. Therefore, no heat treatment or welding can be carried out, because the gas in the gap will expand under the action of heat, resulting in internal micro defects and surface peeling.

● Wire-EDM : 6 Sets

● Brand: Seibu & Sodick

● Capability: Roughness Ra<0.12 / Tolerance +/-0.001mm

● Profile Grinder: 2 Sets

● Brand: WAIDA

● Capability: Roughness <0.05 / Tolerance +/-0.001

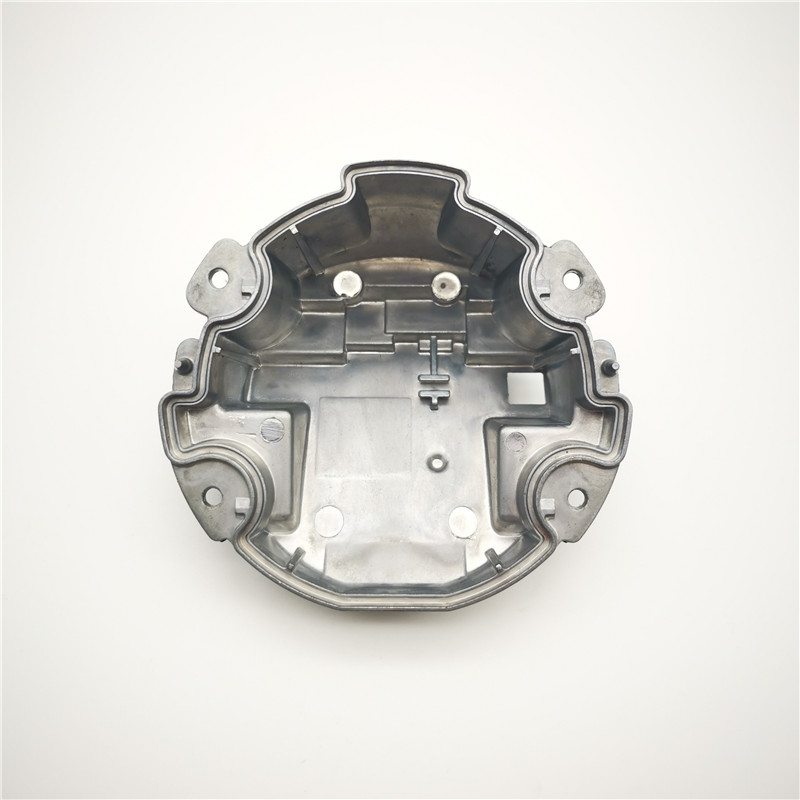

Product detail pictures:

Related Product Guide:

Sticking for the perception of "Creating goods of high quality and making good friends with people today from all around the world", we constantly set the interest of shoppers to begin with for Wholesale Mold Die Supplier – Supporting services for die casting – RAISING-Elec , The product will supply to all over the world, such as: Algeria, Swansea, Pakistan, Facing fierce global market competition, we have launched the brand building strategy and updated the spirit of "human-oriented and faithful service", with an aim to gain global recognition and sustainable development.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.