Steel Stamping Suppliers – High precision stamping product service – RAISING-Elec

Steel Stamping Suppliers – High precision stamping product service – RAISING-Elec Detail:

1. In the process of metal precision stamping parts, the die ensures the dimensional and shape accuracy of metal stamping parts, generally does not damage the surface quality of stamping parts, and the service life of the die is generally long, so the quality of metal stamping is stable.

2. Hardware precision stamping parts can process parts with large size range and complex shape, such as stopwatch of clocks and watches, automobile longitudinal beam and covering parts. Coupled with the cold deformation hardening effect of hardware precision stamping materials, the strength and stiffness of hardware stamping are high.

3. The processing of metal precision stamping parts has the advantages of high production efficiency, convenient operation and easy mechanization and automation. This is because metal stamping depends on stamping dies and stamping equipment to complete the processing. The stroke times of ordinary press can reach dozens of times per minute, and the high-speed pressure can reach hundreds or even thousands of times per minute, and each stamping stroke may get a stamping part.

4. Hardware precision stamping parts generally do not generate chips and broken materials, consume less materials, and do not need other heating equipment. Therefore, it is a material-saving and energy-saving processing method, and the cost of hardware precision stamping parts is low.

● Wire-EDM : 6 Sets

● Brand: Seibu & Sodick

● Capability: Roughness Ra<0.12 / Tolerance +/-0.001mm

● Profile Grinder: 2 Sets

● Brand: WAIDA

● Capability: Roughness <0.05 / Tolerance +/-0.001

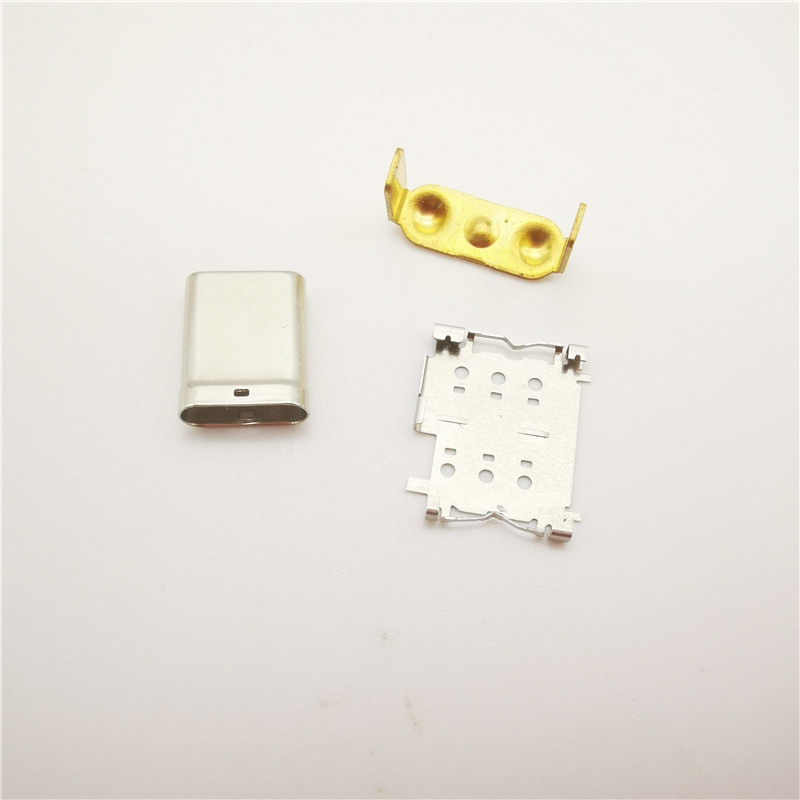

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. Top quality is our life. Purchaser need is our God for Steel Stamping Suppliers – High precision stamping product service – RAISING-Elec , The product will supply to all over the world, such as: Canberra, Finland, Cancun, Aiming to grow to be by far the most professional supplier within this sector in Uganda, we keep researching on the creating procedure and raising the high quality of our principal goods. Till now, the merchandise list has been updated on a regular basis and attracted customers from around the globe. Detailed data can be obtained in our web page and you'll be served with good quality consultant service by our after-sale team. They're going to allow you to get complete acknowledge about our items and make a satisfied negotiation. Small business check out to our factory in Uganda can also be welcome at any time. Hope to obtain your inquiries to get a happy co-operation.

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.