Pins Manufacturers – OEM ODM fastener customization service – RAISING-Elec

Pins Manufacturers – OEM ODM fastener customization service – RAISING-Elec Detail:

Bolt connecting for steel structure is a connection method that connects more than two steel structure parts or components into one by bolts. Bolt connection is the simplest connection method in component pre assembly and structural installation.

Bolted connection is the earliest used in metal structure installation. In the late 1930s, bolt connection was gradually replaced by rivet connection, which was only used as a temporary fixing measure in component assembly. High strength bolt connection method appeared in the 1950s. High strength bolts are made of medium carbon steel or medium carbon alloy steel, and their strength is 2 ~ 3 times higher than that of ordinary bolts. High strength bolt connection has the advantages of convenient construction, safety and reliability. It has been applied in the manufacturing and installation of steel structures in some metallurgical plants since the 1960s.

Bolt specifications commonly used in steel structures include M12, M16, M20, M24 and M30. M is the bolt symbol and the number is the nominal diameter.

Bolts are divided into 10 grades according to performance grades: 3.6, 4.6, 4.8, 5.6, 5.8, 6.8, 8.8, 9.8, 10.9 and 12.9. Bolts above grade 8.8 are made of low-carbon alloy steel or medium carbon steel and are generally referred to as high-strength bolts after heat treatment (quenching and tempering), and bolts below grade 8.8 (excluding grade 8.8, refined ordinary bolts also include grade 8.8) are generally referred to as ordinary bolts. The following table shows the performance grade and mechanical properties of bolts.

● Wire-EDM : 6 Sets

● Brand: Seibu & Sodick

● Capability: Roughness Ra<0.12 / Tolerance +/-0.001mm

● Profile Grinder: 2 Sets

● Brand: WAIDA

● Capability: Roughness <0.05 / Tolerance +/-0.001

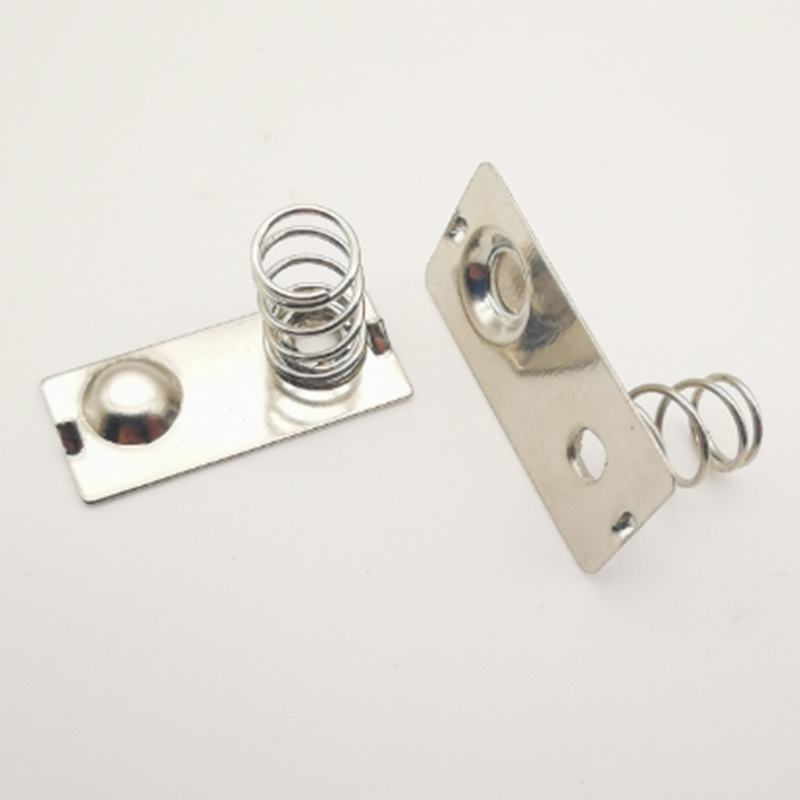

Product detail pictures:

Related Product Guide:

We know that we only thrive if we could guarantee our combined price tag competiveness and quality advantageous at the same time for Pins Manufacturers – OEM ODM fastener customization service – RAISING-Elec , The product will supply to all over the world, such as: Costa Rica, Luxemburg, Slovakia, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to for you of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We are confident that we are going to have a bright prospect and to be distributed all over the world in the years to come.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.