ODM Precision Mold Design Manufacturer – One stop service for fasteners – RAISING-Elec

ODM Precision Mold Design Manufacturer – One stop service for fasteners – RAISING-Elec Detail:

Threads are widely used, from aircraft and cars to water pipes and gas used in our daily life. In many occasions, most threads play the role of fastening connection, followed by the transmission of force and motion. There are also some threads for special purposes. Although there are many kinds, their number is limited.

The long-lasting use of thread is due to its simple structure, reliable performance, convenient disassembly and easy manufacture, which makes it an indispensable structural element in various electromechanical products.

According to the purpose of thread, all kinds of threaded parts should have the following two basic functions: first, good screwing; Second, sufficient strength.

A. According to its structural characteristics and uses, it can be divided into four categories:

Common thread (fastening thread): the tooth shape is triangular, which is used to connect or fasten parts. Ordinary thread can be divided into coarse thread and fine thread according to pitch. Fine thread has high connection strength.

Transmission thread: tooth shapes include trapezoid, rectangle, saw and triangle.

Sealing thread: used for sealing connection, mainly pipe thread, conical thread and conical pipe thread.

Special purpose thread, abbreviated as special thread.

B. Threads can be divided into metric threads (metric threads), British threads, American threads, etc. according to regions (countries). We are used to collectively refer to British threads and American threads as British threads. Its tooth profile angles are 60 ° and 55 °, and the relevant thread parameters such as diameter and pitch adopt English size (inch). In our country, the tooth profile angle is unified as 60 °, and the diameter and pitch series in mm are used. At the same time, this kind of thread is named ordinary thread.

● Wire-EDM : 6 Sets

● Brand: Seibu & Sodick

● Capability: Roughness Ra<0.12 / Tolerance +/-0.001mm

● Profile Grinder: 2 Sets

● Brand: WAIDA

● Capability: Roughness <0.05 / Tolerance +/-0.001

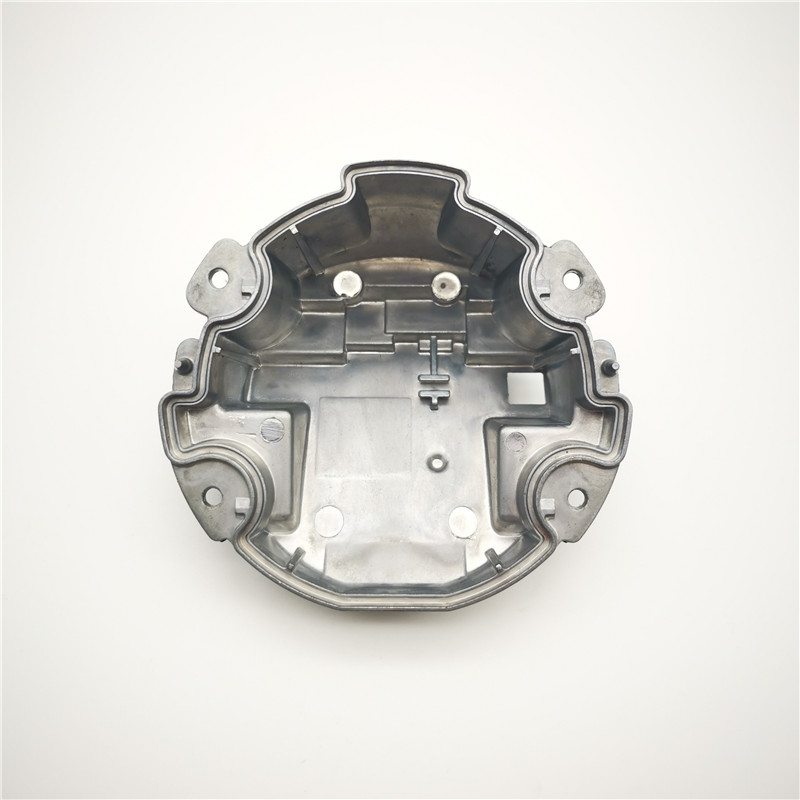

Product detail pictures:

Related Product Guide:

Our team through professional training. Skilled professional knowledge, strong sense of service, to meet the service needs of customers for ODM Precision Mold Design Manufacturer – One stop service for fasteners – RAISING-Elec , The product will supply to all over the world, such as: Malawi, Ecuador, Switzerland, We have been perfectly devoted to the design, R&D, manufacture, sale and service of hair products during 10 years of development. We have introduced and are making full use of internationally advanced technology and equipment, with advantages of skilled workers. "Dedicated to providing reliable customer service" is our aim. We are sincerely looking forward to establishing business relationships with friends from at home and abroad.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.