ODM Metal Die Casting Service – One stop service for die casting – RAISING-Elec

ODM Metal Die Casting Service – One stop service for die casting – RAISING-Elec Detail:

Classification of die casting machines

Hot chamber die casting machine: zinc alloy, magnesium alloy, etc; Cold chamber die casting machine: zinc alloy, magnesium alloy, aluminum alloy, copper alloy, etc; Vertical die casting machine: zinc, aluminum, copper, lead, tin [2]

The difference between hot chamber and cold chamber is whether the injection system of die casting machine is immersed in metal solution. Die casting machines can also be divided into horizontal and vertical.

Common problem

Part of the die casting is not formed and the cavity is not fully filled

Causes: 1. The temperature of die casting die is too low; 2. Low temperature of molten metal; 3. The press pressure is too low; 4. Insufficient liquid metal; The injection speed is too high; 5. The air can’t be discharged.

Adjustment methods: 1 – 2. Increase the temperature of die casting die and liquid metal; 3. Replace high pressure die casting machine; 4. Add enough liquid metal to reduce the injection speed and increase the thickness of the feed inlet.

Quality Control:

The control of die casting die surface temperature is very important for the production of high-quality die castings. Uneven or inappropriate mold temperature will also lead to unstable casting size, ejection casting deformation in the production process, resulting in defects such as thermal pressure, die sticking, surface depression, internal shrinkage cavity and hot bubble. When the mold temperature difference is large, it has different effects on the variables in the production cycle, such as filling time, cooling time and spraying time.

● Wire-EDM : 6 Sets

● Brand: Seibu & Sodick

● Capability: Roughness Ra<0.12 / Tolerance +/-0.001mm

● Profile Grinder: 2 Sets

● Brand: WAIDA

● Capability: Roughness <0.05 / Tolerance +/-0.001

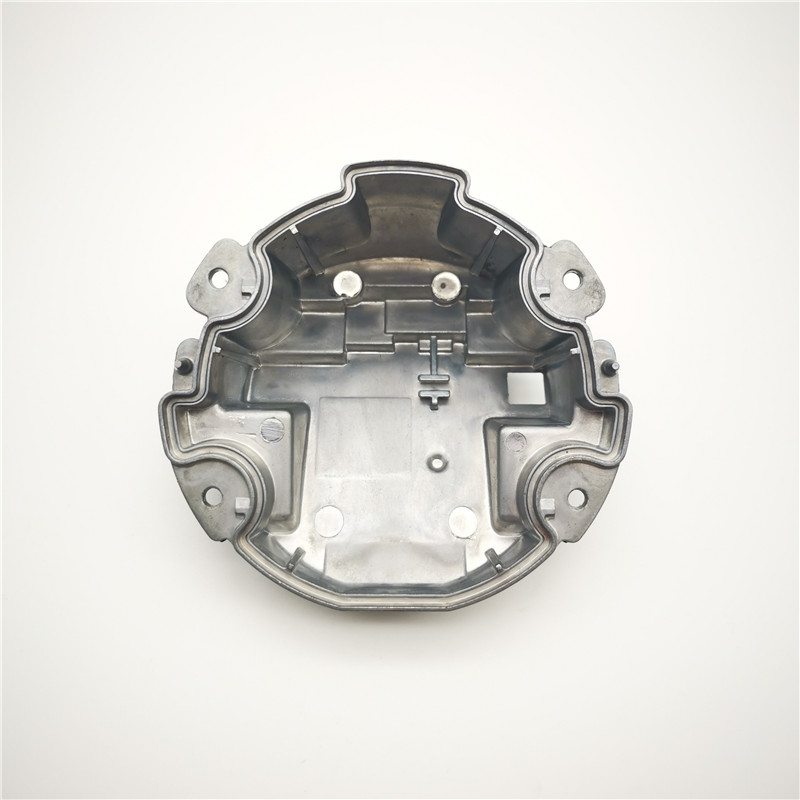

Product detail pictures:

Related Product Guide:

We have been proud from the higher consumer gratification and wide acceptance due to our persistent pursuit of high quality both on product or service and service for ODM Metal Die Casting Service – One stop service for die casting – RAISING-Elec , The product will supply to all over the world, such as: United Arab emirates, Dubai, Manila, Our company always committed to meet your quality demand, price points and sales target. Warmly welcome you open the boundaries of communication. It is our great pleasure to service you if you need a trusted supplier and value information.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!