ODM Galvanized Torsion Springs Manufacturers – One stop service for spring products – RAISING-Elec

ODM Galvanized Torsion Springs Manufacturers – One stop service for spring products – RAISING-Elec Detail:

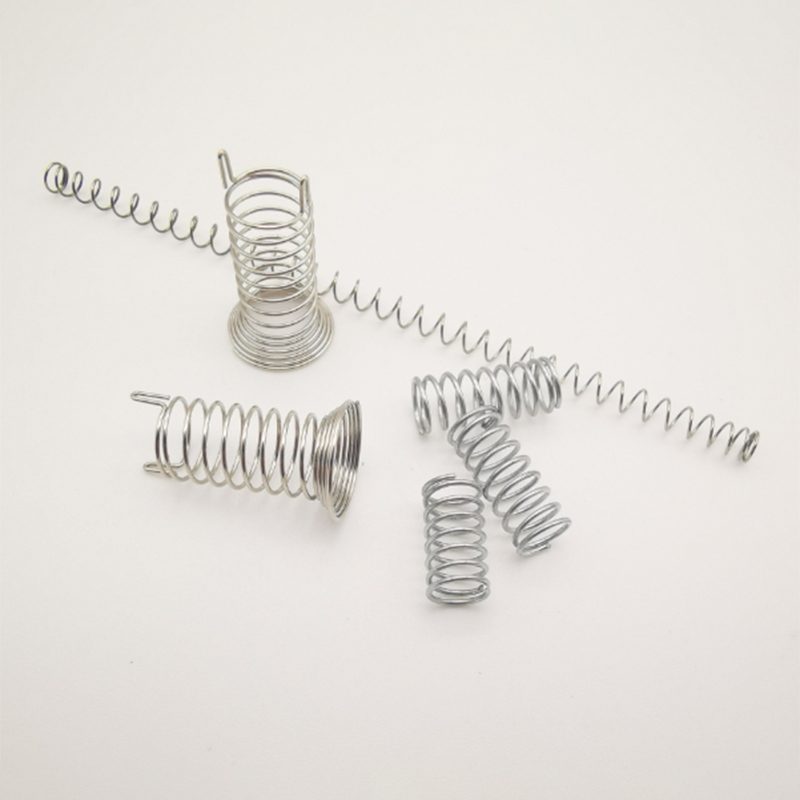

◆ 1. Torsion spring is a spring that bears torsion deformation, and its working part is also tightly wound into a spiral shape. The end structure of torsion spring is a torsion arm processed into various shapes, not a hook ring. The torsion spring uses the lever principle to twist or rotate the elastic material with soft material and high toughness, so that it has great mechanical energy.

◆ 2. A tension spring is a coil spring that bears axial tension. When not under load, the coils of the tension spring are generally tight without clearance.

◆ 3. Compression spring is a coil spring under axial pressure. The material section used is mostly circular, but also made of rectangular and multi strand steel. The spring is generally of equal pitch. The shapes of compression spring include cylindrical, conical, medium convex and medium concave and a small amount of non-circular. There will be a certain gap between the rings of compression spring, When subjected to external load, the spring shrinks and deforms to store deformation energy.

◆ 4. Progressive spring. This spring adopts a design with inconsistent thickness and density. The advantage is that when the pressure is not large, it can absorb the fluctuation of the road through the part with low elastic coefficient to ensure the ride comfort. When the pressure increases to a certain extent, the spring in the thicker part plays the role of supporting the vehicle body. The disadvantage of this spring is that the handling feeling is not direct and the accuracy is poor.

◆ 5. The thickness and density of the linear spring from top to bottom remain unchanged, and the elastic coefficient is a fixed value. The spring of this design can make the vehicle obtain a more stable and linear dynamic response, which is conducive to the driver to better control the vehicle. It is mostly used for performance oriented modified vehicles and competitive vehicles. Of course, the disadvantage is that the comfort is affected.

◆ 6. Compared with the original spring, the short spring is shorter and stronger. Installing the short spring can effectively reduce the center of gravity of the vehicle body, reduce the roll generated during cornering, make the cornering more stable and smooth, and improve the cornering handling of the vehicle.

● Wire-EDM : 6 Sets

● Brand: Seibu & Sodick

● Capability: Roughness Ra<0.12 / Tolerance +/-0.001mm

● Profile Grinder: 2 Sets

● Brand: WAIDA

● Capability: Roughness <0.05 / Tolerance +/-0.001

Product detail pictures:

Related Product Guide:

Our company puts emphasis on the management, the introduction of talented personnel, and the construction of staff building, trying hard to improve the quality and liability consciousness of staff members. Our company successfully attained IS9001 Certification and European CE Certification of ODM Galvanized Torsion Springs Manufacturers – One stop service for spring products – RAISING-Elec , The product will supply to all over the world, such as: Tunisia, Indonesia, Guatemala, All styles appear on our website are for customizing. We meet up to personal requirements with all products of your very own styles. Our concept is to help presenting the confidence of each buyers with the offering of our most sincere service, and the right product.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.