ODM Deep Drawing Stamping Parts Service – High precision stamping product service – RAISING-Elec

ODM Deep Drawing Stamping Parts Service – High precision stamping product service – RAISING-Elec Detail:

1. In the process of metal precision stamping parts, the die ensures the dimensional and shape accuracy of metal stamping parts, generally does not damage the surface quality of stamping parts, and the service life of the die is generally long, so the quality of metal stamping is stable.

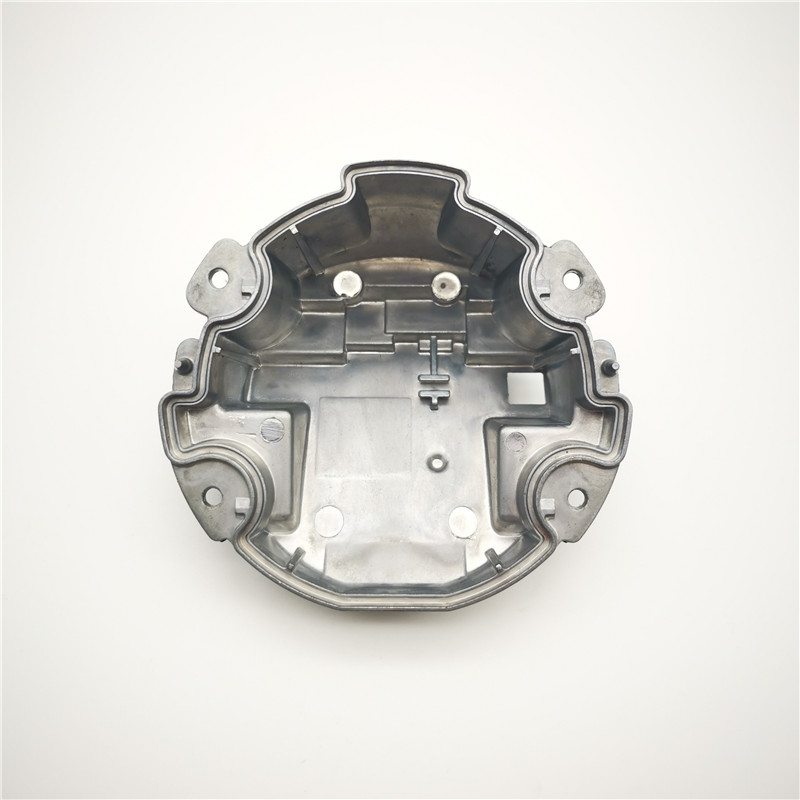

2. Hardware precision stamping parts can process parts with large size range and complex shape, such as stopwatch of clocks and watches, automobile longitudinal beam and covering parts. Coupled with the cold deformation hardening effect of hardware precision stamping materials, the strength and stiffness of hardware stamping are high.

3. The processing of metal precision stamping parts has the advantages of high production efficiency, convenient operation and easy mechanization and automation. This is because metal stamping depends on stamping dies and stamping equipment to complete the processing. The stroke times of ordinary press can reach dozens of times per minute, and the high-speed pressure can reach hundreds or even thousands of times per minute, and each stamping stroke may get a stamping part.

4. Hardware precision stamping parts generally do not generate chips and broken materials, consume less materials, and do not need other heating equipment. Therefore, it is a material-saving and energy-saving processing method, and the cost of hardware precision stamping parts is low.

● Wire-EDM : 6 Sets

● Brand: Seibu & Sodick

● Capability: Roughness Ra<0.12 / Tolerance +/-0.001mm

● Profile Grinder: 2 Sets

● Brand: WAIDA

● Capability: Roughness <0.05 / Tolerance +/-0.001

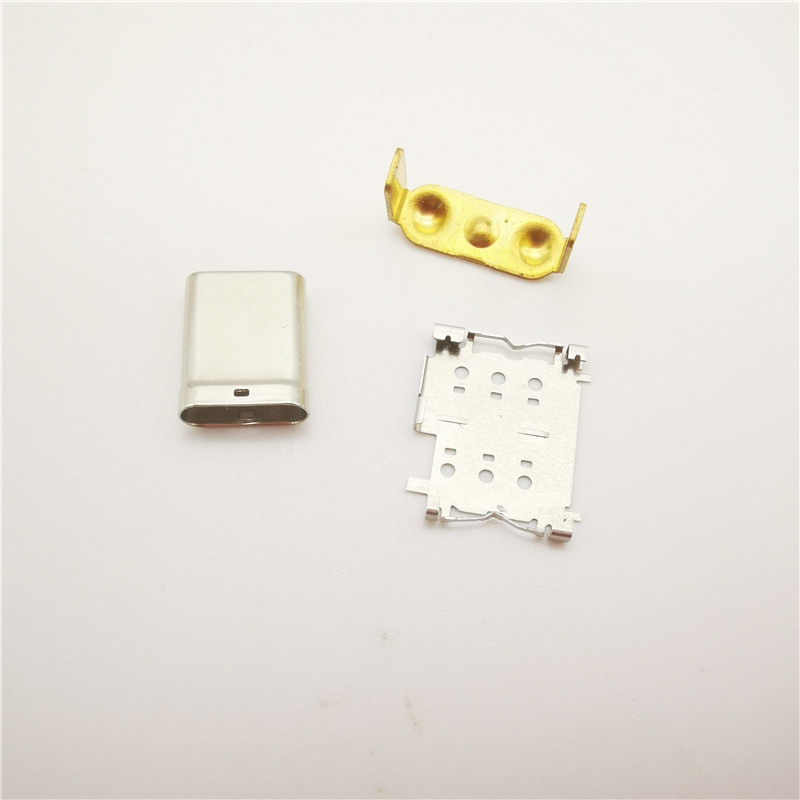

Product detail pictures:

Related Product Guide:

We now have our individual sales group, layout team, technical team, QC crew and package group. Now we have strict high-quality control procedures for each procedure. Also, all of our workers are experienced in printing discipline for ODM Deep Drawing Stamping Parts Service – High precision stamping product service – RAISING-Elec , The product will supply to all over the world, such as: Chicago, Vietnam, Ethiopia, Our Company policy is "quality first, to be better and stronger, sustainable development" . Our pursuit goals is "for society, customers, employees, partners and enterprises to seek reasonable benefit". We aspirate to do cooperate with all different the auto parts manufacturers, repair shop, auto peer , then create a beautiful future! Thank you for taking time to browse our website and we would welcome any suggestions you may have that can help us to improve our site.

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.