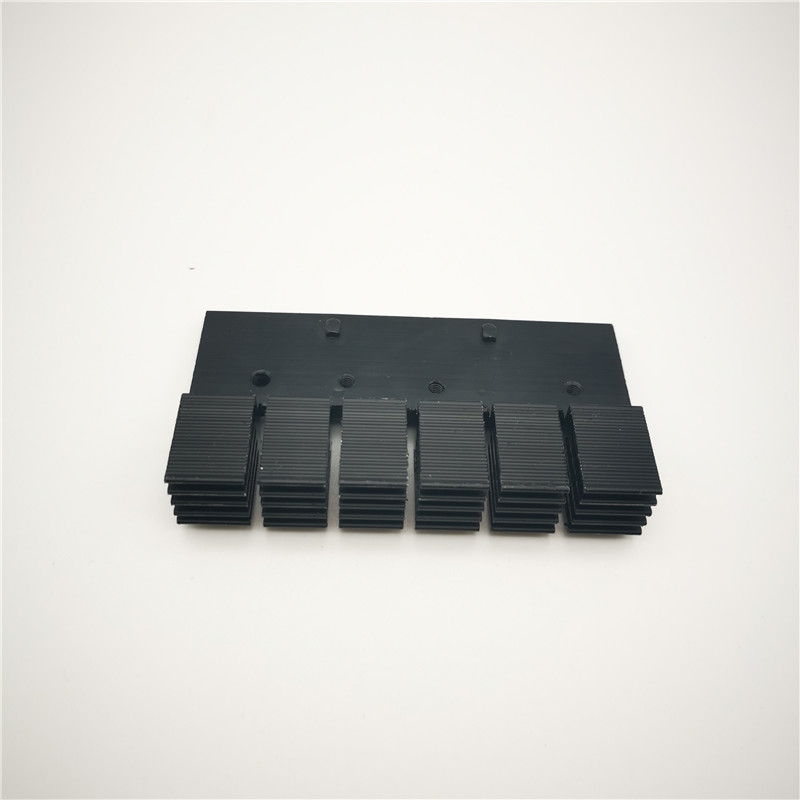

ODM Custom Mechanical Parts Suppliers – Heatsink customization according to customers’ request – RAISING-Elec

ODM Custom Mechanical Parts Suppliers – Heatsink customization according to customers’ request – RAISING-Elec Detail:

Material: stainless steel titanium alloy

Processing equipment: precision grinder processing, CNC processing

Accuracy requirement: 0.005mm

Surface treatment: chrome plating

Machining scope of Raising:

1. Precision machining.

2. Precision equipment parts processing.

3. Processing of non-standard spare parts.

4. Machining of precision special-shaped parts.

5. Hardware and mechanical parts processing.

6. Surface treatment of various mechanical parts.

With the development of computer control technology, more and more machine tools are integrated with CNC system, in order to realize the automation of processing, avoid manual operation errors, and improve the processing accuracy and stability. Therefore, CNC machine tools are widely used in the field of precision parts manufacturing.

(1) CNC processing precision of fine metal shaft is high, with stable processing quality;

(2) It can carry out multi-coordinate linkage and process parts with disorderly shapes.

(3) When the CNC parts of fine hardware are changed, only the NC program needs to be changed to save the production preparation time.

(4) The machine tool itself has high precision and rigidity, and can choose the advantageous processing amount, and the output rate is high (generally 3 to 5 times of that of the general machine tool).

(5) Machine tools are highly automated and can reduce labor intensity.

● Wire-EDM : 6 Sets

● Brand: Seibu & Sodick

● Capability: Roughness Ra<0.12 / Tolerance +/-0.001mm

● Profile Grinder: 2 Sets

● Brand: WAIDA

● Capability: Roughness <0.05 / Tolerance +/-0.001

Product detail pictures:

Related Product Guide:

Persisting in "High quality, Prompt Delivery, Aggressive Price", now we have established long-term cooperation with consumers from equally overseas and domestically and get new and old clients' large comments for ODM Custom Mechanical Parts Suppliers – Heatsink customization according to customers’ request – RAISING-Elec , The product will supply to all over the world, such as: Argentina, Munich, UK, We'll initiate the second phase of our development strategy. Our company regards "reasonable prices, efficient production time and good after-sales service" as our tenet. If you are interested in any of our products and solutions or would like to discuss a custom order, make sure you feel free to contact us. We've been looking forward to forming successful business relationships with new clients around the world in the near future.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!