ODM Custom Mechanical Components Manufacturers – OEM ODM Servics for Metal Parts – RAISING-Elec

ODM Custom Mechanical Components Manufacturers – OEM ODM Servics for Metal Parts – RAISING-Elec Detail:

Raisingelec has been engaged in metal trade for 10 years. Our large number of factory partners in China have enabled us to respond quickly to customer orders and have a strong cost competitive advantage and quality reliability. At the same time, for some difficult products , We can also quickly give a solution.

We can provide customers with a full range of metal supporting services, including stamping, machining ,die casting, fastener ,spring and other special customized metal products.

In short, our advantage in metal parts far exceeds that of other single factories. We can not only meet the needs of customers for large quantities of orders, but also respond to the small production requirements of customers quickly.

About Machining:

In the field of processing and manufacturing industry, what we often call machining is a process of changing the overall dimension or performance of the workpiece with processing machinery.

The production and processing process is divided into cold processing and hot processing according to the temperature state of the workpiece to be processed. Generally, it is processed at normal temperature without causing chemical or phase changes of the workpiece, which is called cold processing. Generally, processing above or below normal temperature will cause chemical or phase changes of the workpiece, which is called hot processing. Cold working can be divided into cutting and pressure machining according to the difference of machining methods. Heat treatment, forging, casting and welding are common in hot working.

Cold and heat treatment is often used in the assembly process of mechanical equipment. For example, during bearing assembly, the inner ring is often cooled in liquid nitrogen to shrink its size, the outer ring is properly heated to enlarge its size, and then it is assembled together. The wheel outer ring of the train is also sleeved on the substrate by heating, and its firmness can be ensured when cooling (this method is still applied to the transfer process of some parts).

● Wire-EDM : 6 Sets

● Brand: Seibu & Sodick

● Capability: Roughness Ra<0.12 / Tolerance +/-0.001mm

● Profile Grinder: 2 Sets

● Brand: WAIDA

● Capability: Roughness <0.05 / Tolerance +/-0.001

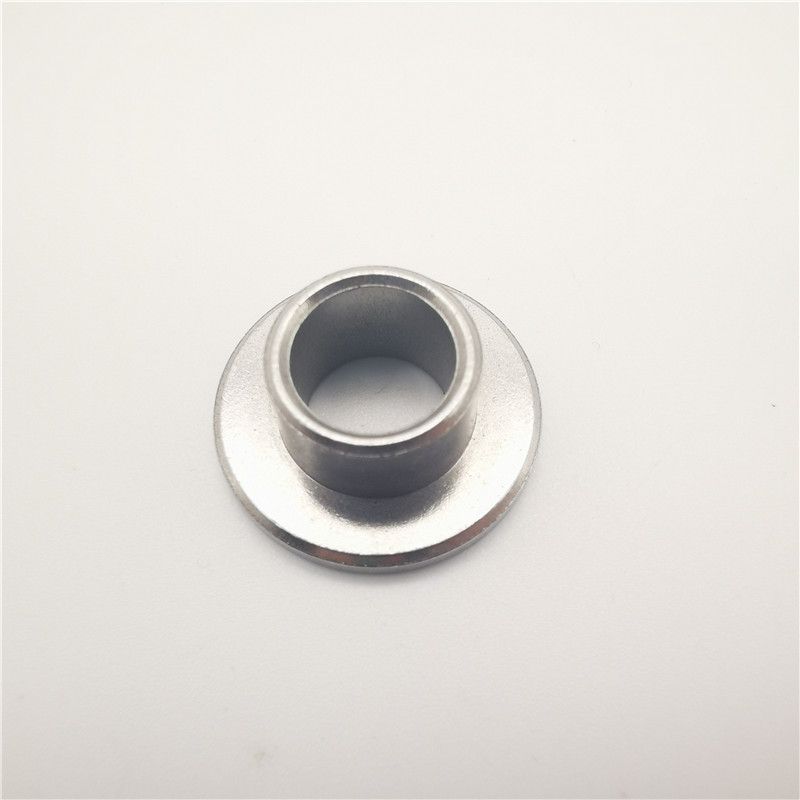

Product detail pictures:

Related Product Guide:

To continuously increase the administration process by virtue of the rule of "sincerely, good religion and excellent are the base of company development", we commonly absorb the essence of linked goods internationally, and continually build new solutions to fulfill the requires of shoppers for ODM Custom Mechanical Components Manufacturers – OEM ODM Servics for Metal Parts – RAISING-Elec , The product will supply to all over the world, such as: Istanbul, Accra, Vancouver, Our qualified engineering team will usually be prepared to serve you for consultation and feedback. We've been able to also deliver you with absolutely free samples to meet your needs. Best efforts might be made to offer you the ideal service and items. For anyone who is interested in our company and products, be sure to make contact with us by sending us emails or contact us right away. In order to know our solutions and organization. ar more, you can come to our factory to determine it. We are about to usually welcome guests from around the globe to our corporation. o create small business relations with us. Please genuinely feel no cost to speak to us for enterprise. nd we believe we have been gonna share the most effective trading practical experience with all our merchants.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.