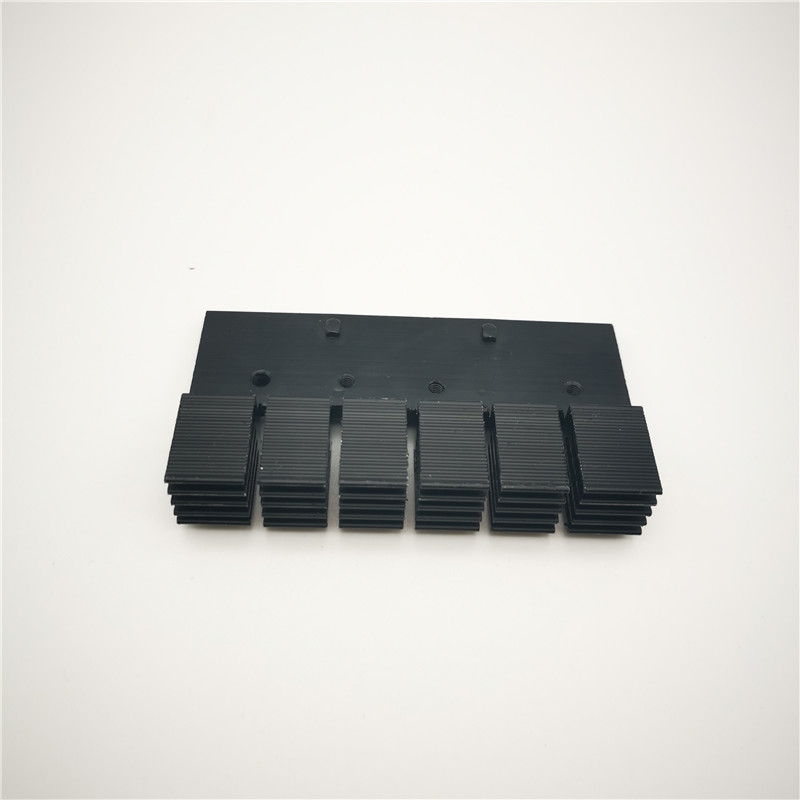

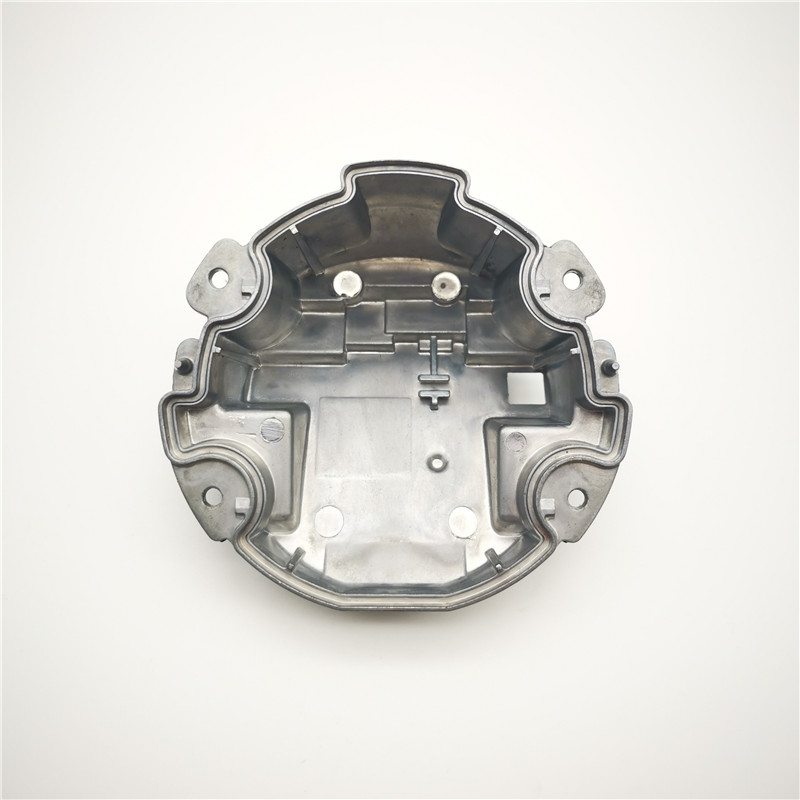

ODM Custom Machined Metal Components Supplier – Heatsink customization according to customers’ request – RAISING-Elec

ODM Custom Machined Metal Components Supplier – Heatsink customization according to customers’ request – RAISING-Elec Detail:

Material: stainless steel titanium alloy

Processing equipment: precision grinder processing, CNC processing

Accuracy requirement: 0.005mm

Surface treatment: chrome plating

Machining scope of Raising:

1. Precision machining.

2. Precision equipment parts processing.

3. Processing of non-standard spare parts.

4. Machining of precision special-shaped parts.

5. Hardware and mechanical parts processing.

6. Surface treatment of various mechanical parts.

With the development of computer control technology, more and more machine tools are integrated with CNC system, in order to realize the automation of processing, avoid manual operation errors, and improve the processing accuracy and stability. Therefore, CNC machine tools are widely used in the field of precision parts manufacturing.

(1) CNC processing precision of fine metal shaft is high, with stable processing quality;

(2) It can carry out multi-coordinate linkage and process parts with disorderly shapes.

(3) When the CNC parts of fine hardware are changed, only the NC program needs to be changed to save the production preparation time.

(4) The machine tool itself has high precision and rigidity, and can choose the advantageous processing amount, and the output rate is high (generally 3 to 5 times of that of the general machine tool).

(5) Machine tools are highly automated and can reduce labor intensity.

● Wire-EDM : 6 Sets

● Brand: Seibu & Sodick

● Capability: Roughness Ra<0.12 / Tolerance +/-0.001mm

● Profile Grinder: 2 Sets

● Brand: WAIDA

● Capability: Roughness <0.05 / Tolerance +/-0.001

Product detail pictures:

Related Product Guide:

We will make just about every exertion for being excellent and perfect, and speed up our actions for standing during the rank of worldwide top-grade and high-tech enterprises for ODM Custom Machined Metal Components Supplier – Heatsink customization according to customers’ request – RAISING-Elec , The product will supply to all over the world, such as: Kenya, Iceland, Lithuania, "Create Values,Serving Customer!" is the aim we pursue. We sincerely hope that all customers will establish long term and mutually beneficial cooperation with us.If you wish to get more details about our company, Please contact with us now!

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!