Metal Stamping Mesh Manufacturer – One stop service for metal stamping – RAISING-Elec

Metal Stamping Mesh Manufacturer – One stop service for metal stamping – RAISING-Elec Detail:

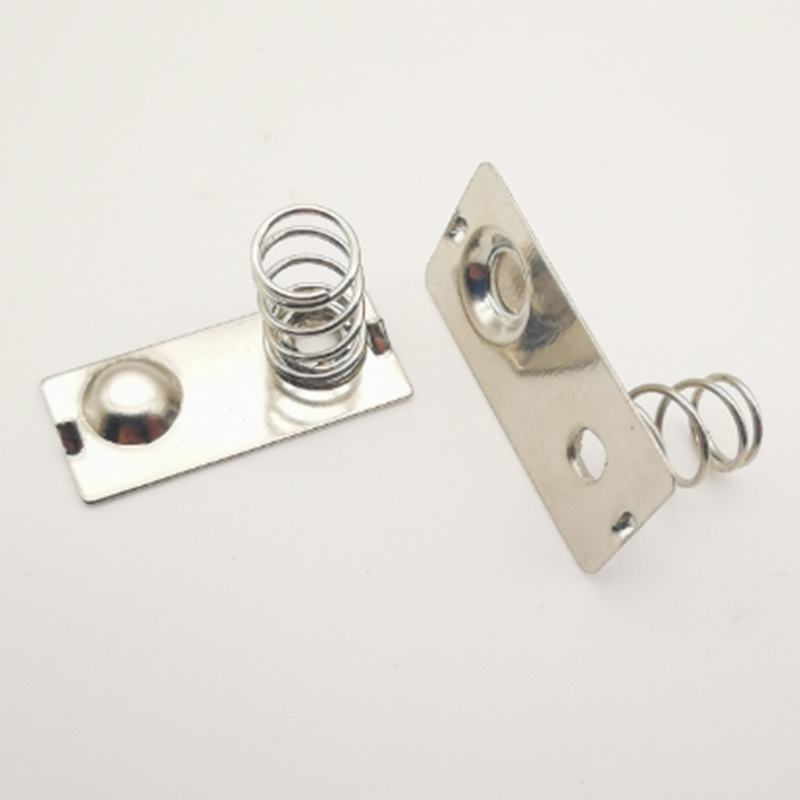

Stamping parts are sheet metal parts, that is, parts that can be processed by stamping, bending, stretching and other means. A general definition is – parts with constant thickness in the processing process. The corresponding parts are casting parts, forging parts, machining parts, etc. for example, the iron shell outside the car is sheet metal, and some kitchen utensils made of stainless steel are also sheet metal.

Stamping is a kind of automobile repair technology, that is to repair the deformed part of the automobile metal shell. For example, if the car body shell is hit with a pit, it can be restored to its original state through sheet metal.

Generally speaking, the basic equipment of stamping parts factory includes shear machine, CNC punching machine / laser, plasma, water jet cutting machine / combination machine, bending machine and various auxiliary equipment, such as uncoiler, leveling machine, deburring machine, spot welder, etc( Guide: how to buy high-quality metal stamping parts (four methods).

Stamping parts are sometimes used as metal pulling. Generally, some metal sheets are stamped by hand or die to produce plastic deformation to form the desired shape and size, and more complex parts can be formed by welding or a small amount of machining, such as chimney, sheet iron furnace and automobile shell commonly used in families.

Stamping parts processing is called sheet metal processing. Specifically, for example, the use of plates to make chimneys, iron barrels, oil tanks, oil pots, ventilation pipes, large and small ends of elbows, Tianyuan places, funnel shapes, etc. the main processes are shearing, bending and edge buckle, bending forming, welding, riveting, etc., which requires certain geometric knowledge.

● Wire-EDM : 6 Sets

● Brand: Seibu & Sodick

● Capability: Roughness Ra<0.12 / Tolerance +/-0.001mm

● Profile Grinder: 2 Sets

● Brand: WAIDA

● Capability: Roughness <0.05 / Tolerance +/-0.001

Product detail pictures:

Related Product Guide:

Excellent 1st,and Client Supreme is our guideline to deliver the ideal provider to our prospects.Nowadays, we have been seeking our best to become certainly one of the most effective exporters in our discipline to meet shoppers more require for Metal Stamping Mesh Manufacturer – One stop service for metal stamping – RAISING-Elec , The product will supply to all over the world, such as: Saudi Arabia, Nigeria, St. Petersburg, Our business activities and processes are engineered to make sure our customers have access to widest range of products with the shortest supply time lines. This achievement is made possible by our highly skilled and experienced team. We look for people who want to grow with us around the globe and stand out from the crowd. We now have people who embrace tomorrow, have vision, love stretching their minds and going far beyond what they thought was achievable.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!