Die Casting Products Service – OEM ODM for die casting – RAISING-Elec

Die Casting Products Service – OEM ODM for die casting – RAISING-Elec Detail:

Die casting is a metal casting process, which is characterized by using the inner cavity of the die to apply high pressure to the molten metal. Molds are usually made of higher strength alloys, which is somewhat similar to injection molding. Most die castings are iron free, such as zinc, copper, aluminum, magnesium, lead, tin and lead tin alloys and their alloys. Depending on the type of die casting, it is necessary to use cold chamber die casting machine or hot chamber die casting machine.

The cost of casting equipment and molds is high, so the die-casting process is generally only used for mass production of a large number of products. It is relatively easy to manufacture die-casting parts, which generally requires only four main steps, and the single cost increment is very low. Die casting is especially suitable for manufacturing a large number of small and medium-sized castings, so die casting is the most widely used in various casting processes. Compared with other casting technologies, the surface of die casting is smoother and has higher dimensional consistency.

Based on the traditional die casting process, several improved processes were born, including the non porous die casting process to reduce casting defects and eliminate pores. It is a direct injection process mainly used for processing zinc, which can reduce waste and increase yield.

The metals used for die casting mainly include zinc, copper, aluminum, magnesium, lead, tin and lead tin alloys. Although pressed cast iron is rare, it is also feasible. Special die casting metals include Zamak, aluminum zinc alloy and American Aluminum Association standards: aa380, aa384, aa386, aa390 and AZ91D magnesium. The characteristics of die casting of various metals are as follows:

Zinc: the most easily die-casting metal. It is very economical to manufacture small parts, easy to coat, high compressive strength and plasticity, and long casting life.

Aluminum: light weight, complex manufacturing and thin-walled castings have high dimensional stability, strong corrosion resistance, good mechanical properties, high thermal conductivity and conductivity, and high strength at high temperature.

Magnesium: easy to machine, high strength to weight ratio, the lightest of commonly used die-casting metals.

Copper: it has high hardness and strong corrosion resistance. Among the commonly used die-casting metals, it has the best mechanical properties, wear resistance and strength close to that of steel.

Lead and tin: high density, high dimensional accuracy, can be used as special anti-corrosion parts. For public health reasons, this alloy cannot be used as food processing and storage equipment. An alloy of lead, tin and antimony (sometimes with a little copper) can be used to make manual type and bronzing in letterpress printing.

● Wire-EDM : 6 Sets

● Brand: Seibu & Sodick

● Capability: Roughness Ra<0.12 / Tolerance +/-0.001mm

● Profile Grinder: 2 Sets

● Brand: WAIDA

● Capability: Roughness <0.05 / Tolerance +/-0.001

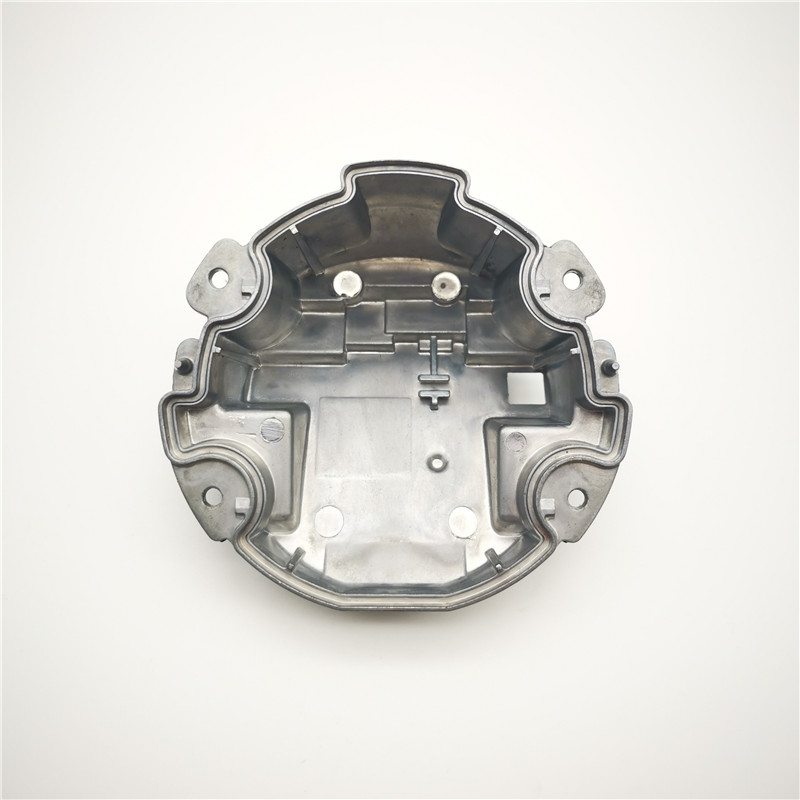

Product detail pictures:

Related Product Guide:

By using a full scientific excellent administration method, great quality and fantastic religion, we get good reputation and occupied this discipline for Die Casting Products Service – OEM ODM for die casting – RAISING-Elec , The product will supply to all over the world, such as: Los Angeles, America, Bogota, Immediate and expert after-sale service supplied by our consultant group has happy our buyers. Comprehensive Info and parameters from the merchandise will probably be sent to you for any comprehensive acknowledge. Free samples may be delivered and company check out to our corporation. n Morocco for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.