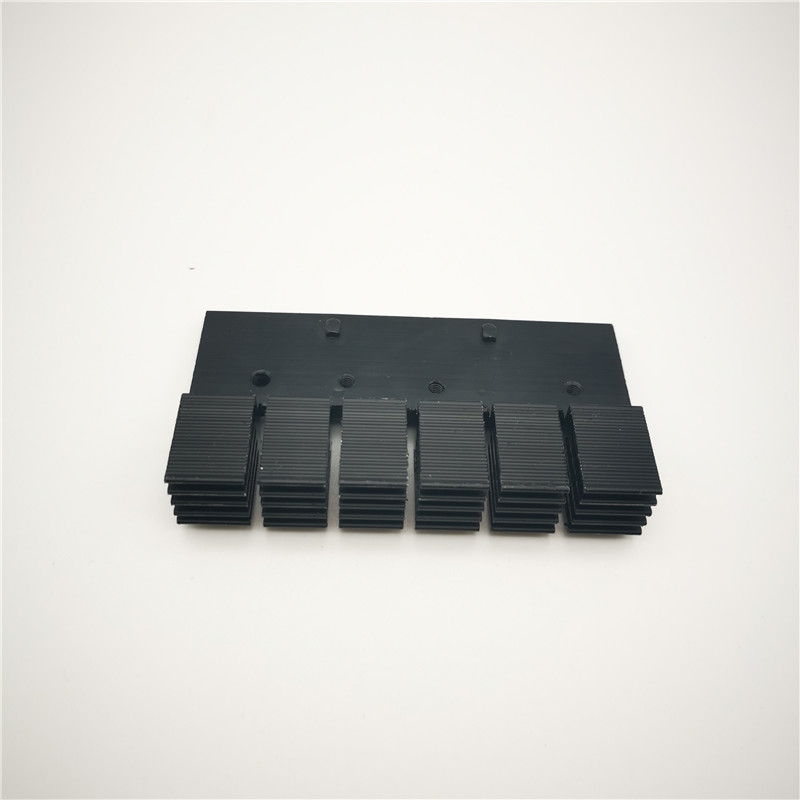

Custom Cnc Precision Machining Manufacturer – Heatsink customization according to customers’ request – RAISING-Elec

Custom Cnc Precision Machining Manufacturer – Heatsink customization according to customers’ request – RAISING-Elec Detail:

Material: stainless steel titanium alloy

Processing equipment: precision grinder processing, CNC processing

Accuracy requirement: 0.005mm

Surface treatment: chrome plating

Machining scope of Raising:

1. Precision machining.

2. Precision equipment parts processing.

3. Processing of non-standard spare parts.

4. Machining of precision special-shaped parts.

5. Hardware and mechanical parts processing.

6. Surface treatment of various mechanical parts.

With the development of computer control technology, more and more machine tools are integrated with CNC system, in order to realize the automation of processing, avoid manual operation errors, and improve the processing accuracy and stability. Therefore, CNC machine tools are widely used in the field of precision parts manufacturing.

(1) CNC processing precision of fine metal shaft is high, with stable processing quality;

(2) It can carry out multi-coordinate linkage and process parts with disorderly shapes.

(3) When the CNC parts of fine hardware are changed, only the NC program needs to be changed to save the production preparation time.

(4) The machine tool itself has high precision and rigidity, and can choose the advantageous processing amount, and the output rate is high (generally 3 to 5 times of that of the general machine tool).

(5) Machine tools are highly automated and can reduce labor intensity.

● Wire-EDM : 6 Sets

● Brand: Seibu & Sodick

● Capability: Roughness Ra<0.12 / Tolerance +/-0.001mm

● Profile Grinder: 2 Sets

● Brand: WAIDA

● Capability: Roughness <0.05 / Tolerance +/-0.001

Product detail pictures:

Related Product Guide:

We try for excellence, service the customers", hopes to be the most effective cooperation workforce and dominator company for staff, suppliers and shoppers, realizes price share and ongoing marketing for Custom Cnc Precision Machining Manufacturer – Heatsink customization according to customers’ request – RAISING-Elec , The product will supply to all over the world, such as: venezuela, Libya, Mombasa, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. We are willing to cooperate with business friends from at home and abroad and create a great future together.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.