Cnc Precision Machining Service – OEM ODM Metal Parts service – RAISING-Elec

Cnc Precision Machining Service – OEM ODM Metal Parts service – RAISING-Elec Detail:

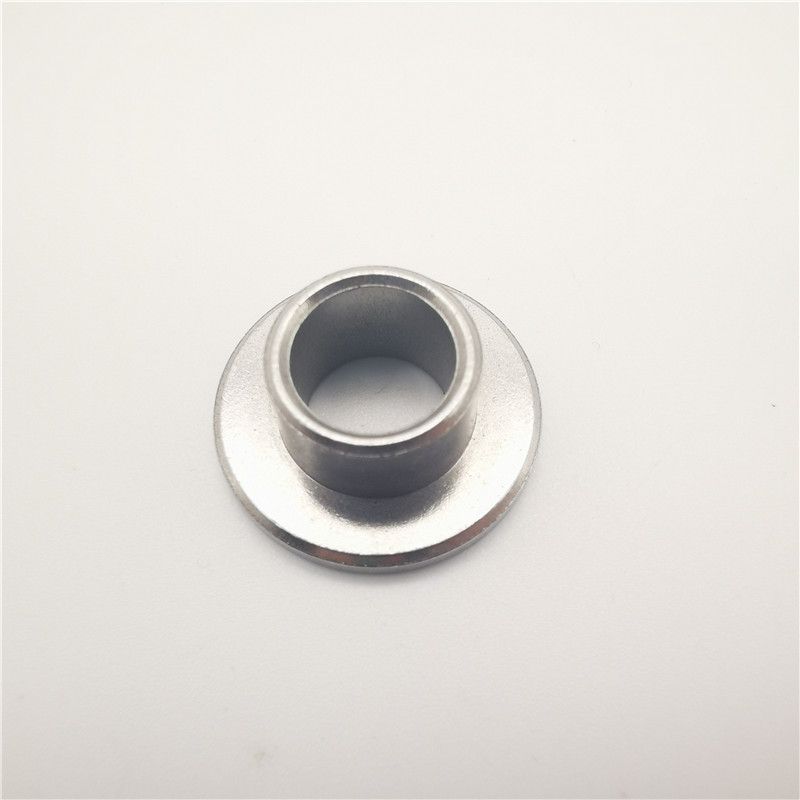

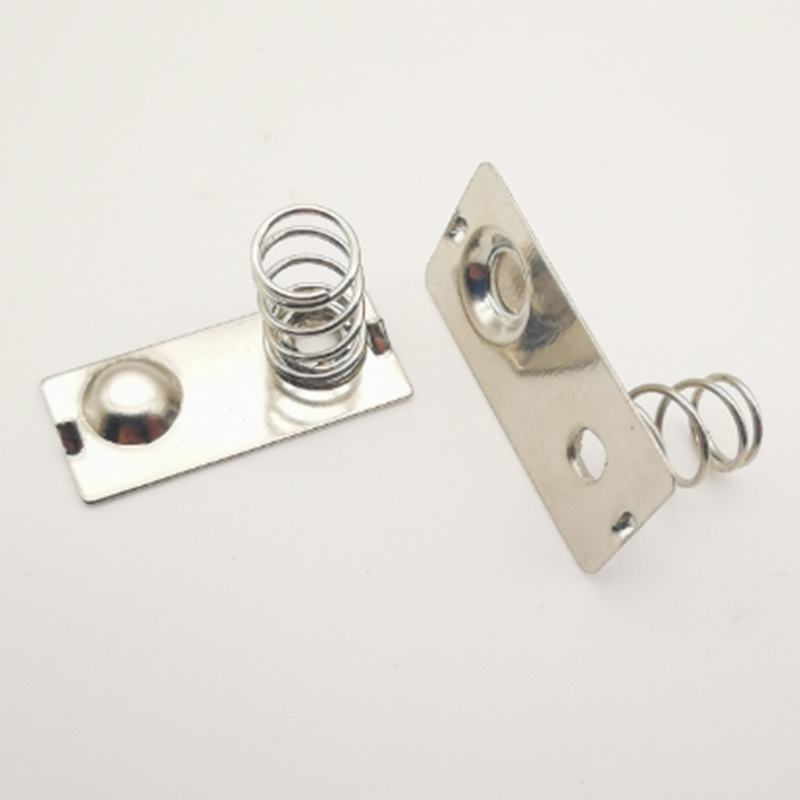

Material: SKD11

Processing equipment: precision milling machine, grinder, slow wire processing

Accuracy requirement: 0.005mm

Surface treatment: nickel plating

Machining scope of Raising:

1. Precision machining.

2. Precision equipment parts processing.

3. Processing of non-standard spare parts.

4. Machining of precision special-shaped parts.

5. Hardware and mechanical parts processing.

6. Surface treatment of various mechanical parts.

In the field of processing and manufacturing industry, what we often call machining is a process of changing the overall dimension or performance of the workpiece with processing machinery.

The production and processing process is divided into cold processing and hot processing according to the temperature state of the workpiece to be processed. Generally, it is processed at normal temperature without causing chemical or phase changes of the workpiece, which is called cold processing. Generally, processing above or below normal temperature will cause chemical or phase changes of the workpiece, which is called hot processing. Cold working can be divided into cutting and pressure machining according to the difference of machining methods. Heat treatment, forging, casting and welding are common in hot working.

Cold and heat treatment is often used in the assembly process of mechanical equipment. For example, during bearing assembly, the inner ring is often cooled in liquid nitrogen to shrink its size, the outer ring is properly heated to enlarge its size, and then it is assembled together. The wheel outer ring of the train is also sleeved on the substrate by heating, and its firmness can be ensured when cooling (this method is still applied to the transfer process of some parts).

● Wire-EDM : 6 Sets

● Brand: Seibu & Sodick

● Capability: Roughness Ra<0.12 / Tolerance +/-0.001mm

● Profile Grinder: 2 Sets

● Brand: WAIDA

● Capability: Roughness <0.05 / Tolerance +/-0.001

Product detail pictures:

Related Product Guide:

Our organization promises all customers with the first-class products and solutions and the most satisfying post-sale service. We warmly welcome our regular and new clients to join us for Cnc Precision Machining Service – OEM ODM Metal Parts service – RAISING-Elec , The product will supply to all over the world, such as: Armenia, Romania, Bogota, Being guided by customer demands, aiming at improving the efficiency and quality of customer service, we constantly improve goods and give more detailed services. We sincerely welcome friends to negotiate business and start cooperation with us. We hope to join hands with friends in different industries to create a brilliant future.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.