China OEM Stamping Fabrication Parts Manufacturer – High precision stamping product service – RAISING-Elec

China OEM Stamping Fabrication Parts Manufacturer – High precision stamping product service – RAISING-Elec Detail:

1. In the process of metal precision stamping parts, the die ensures the dimensional and shape accuracy of metal stamping parts, generally does not damage the surface quality of stamping parts, and the service life of the die is generally long, so the quality of metal stamping is stable.

2. Hardware precision stamping parts can process parts with large size range and complex shape, such as stopwatch of clocks and watches, automobile longitudinal beam and covering parts. Coupled with the cold deformation hardening effect of hardware precision stamping materials, the strength and stiffness of hardware stamping are high.

3. The processing of metal precision stamping parts has the advantages of high production efficiency, convenient operation and easy mechanization and automation. This is because metal stamping depends on stamping dies and stamping equipment to complete the processing. The stroke times of ordinary press can reach dozens of times per minute, and the high-speed pressure can reach hundreds or even thousands of times per minute, and each stamping stroke may get a stamping part.

4. Hardware precision stamping parts generally do not generate chips and broken materials, consume less materials, and do not need other heating equipment. Therefore, it is a material-saving and energy-saving processing method, and the cost of hardware precision stamping parts is low.

● Wire-EDM : 6 Sets

● Brand: Seibu & Sodick

● Capability: Roughness Ra<0.12 / Tolerance +/-0.001mm

● Profile Grinder: 2 Sets

● Brand: WAIDA

● Capability: Roughness <0.05 / Tolerance +/-0.001

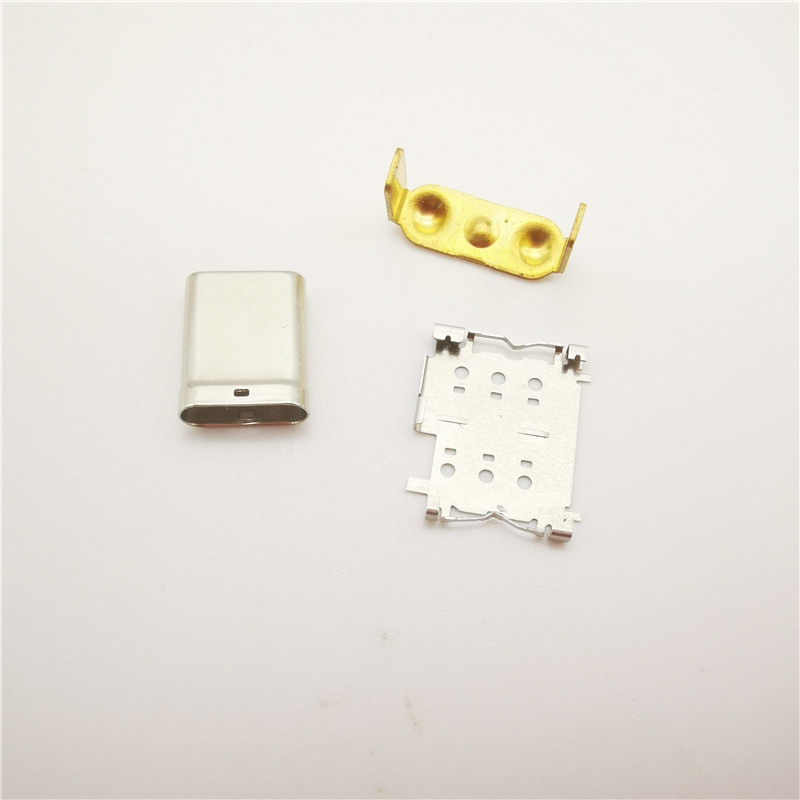

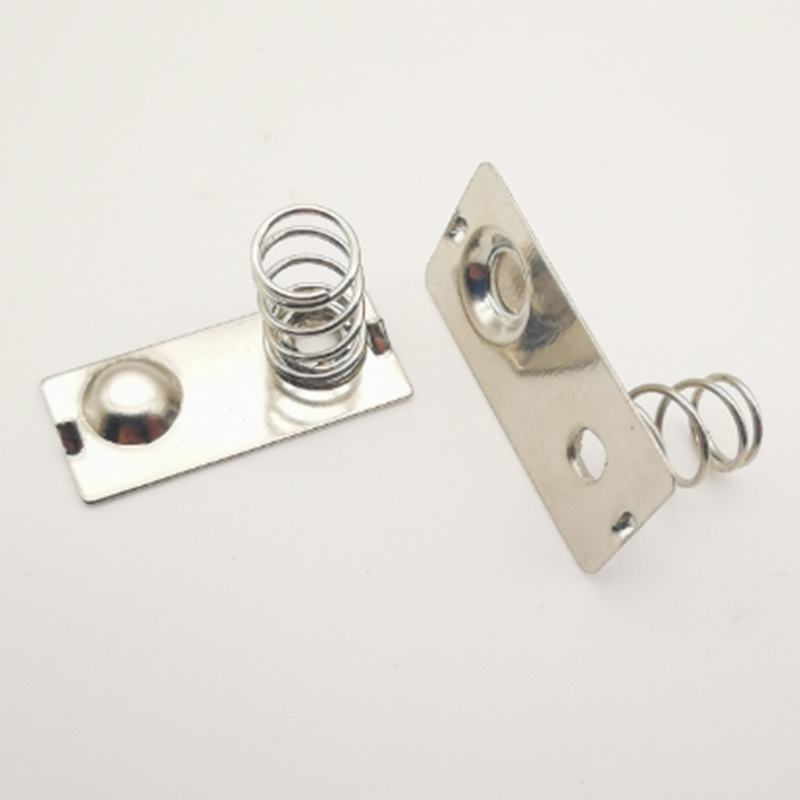

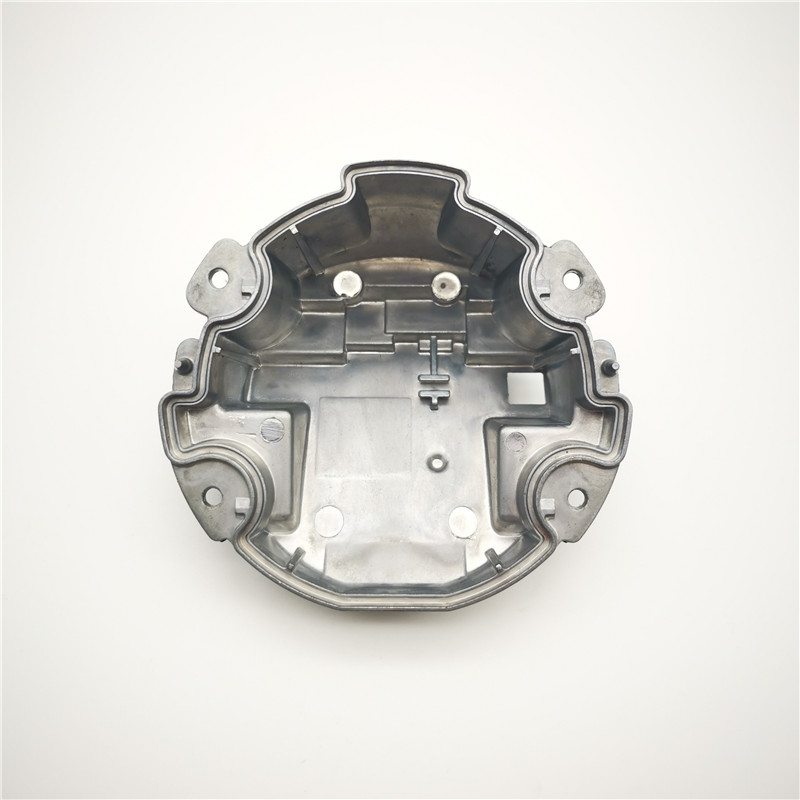

Product detail pictures:

Related Product Guide:

Our business puts emphasis over the administration, the introduction of talented staff, plus the construction of team building, attempting hard to boost the standard and liability consciousness of personnel customers. Our corporation successfully attained IS9001 Certification and European CE Certification of China OEM Stamping Fabrication Parts Manufacturer – High precision stamping product service – RAISING-Elec , The product will supply to all over the world, such as: Rome, Czech, California, If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!