China OEM Progressive Die Cold Stamping Mould – Supporting services for die casting – RAISING-Elec

China OEM Progressive Die Cold Stamping Mould – Supporting services for die casting – RAISING-Elec Detail:

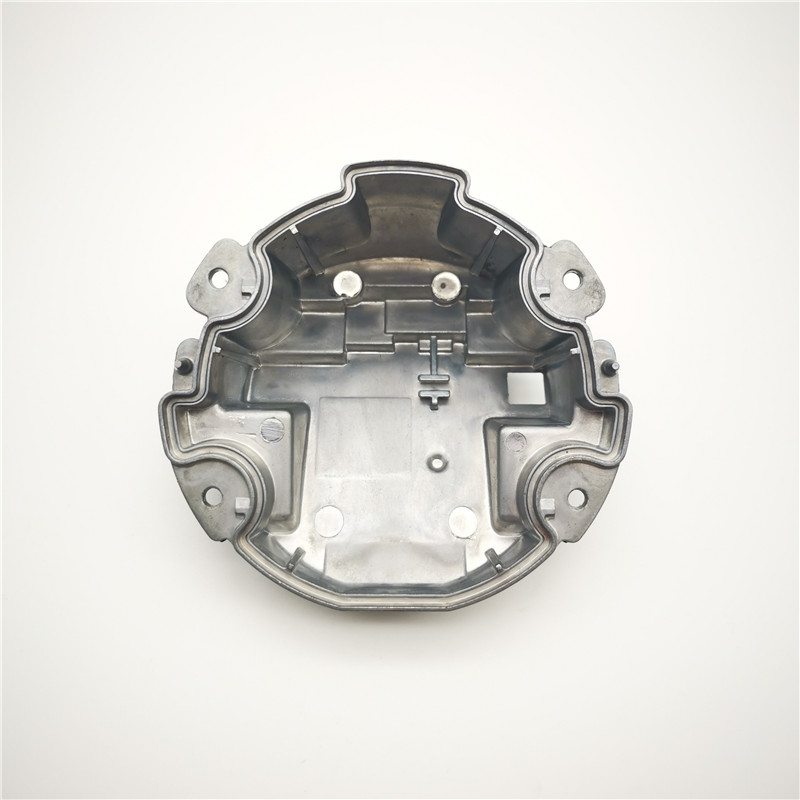

The advantages of die casting include excellent dimensional accuracy. Usually, this depends on the casting material. The typical value is that the error is 0.1mm for the first 2.5cm size, and the error increases by 0.002 mm for each additional 1cm. Compared with other casting processes, its casting surface is smooth, and the fillet radius is about 1-2.5 microns. Castings with a wall thickness of about 0.75 mm can be manufactured relative to sandbox or permanent die casting.

It can directly cast internal structures, such as wire sleeves, heating elements and high-strength bearing surfaces. Other advantages include its ability to reduce or avoid secondary machining, high production speed, casting tensile strength up to 415 MPa, and high fluidity metal casting.

The biggest disadvantage of die casting is the high cost. Casting equipment, molds and mold related components are expensive compared with other casting methods. Therefore, it is more economical to produce a large number of products when manufacturing die castings. Other disadvantages include: this process is only applicable to metals with high fluidity, and the casting mass must be between 30g and 10kg [5] 。 In normal die casting, the last batch of castings will always have pores. Therefore, no heat treatment or welding can be carried out, because the gas in the gap will expand under the action of heat, resulting in internal micro defects and surface peeling.

● Wire-EDM : 6 Sets

● Brand: Seibu & Sodick

● Capability: Roughness Ra<0.12 / Tolerance +/-0.001mm

● Profile Grinder: 2 Sets

● Brand: WAIDA

● Capability: Roughness <0.05 / Tolerance +/-0.001

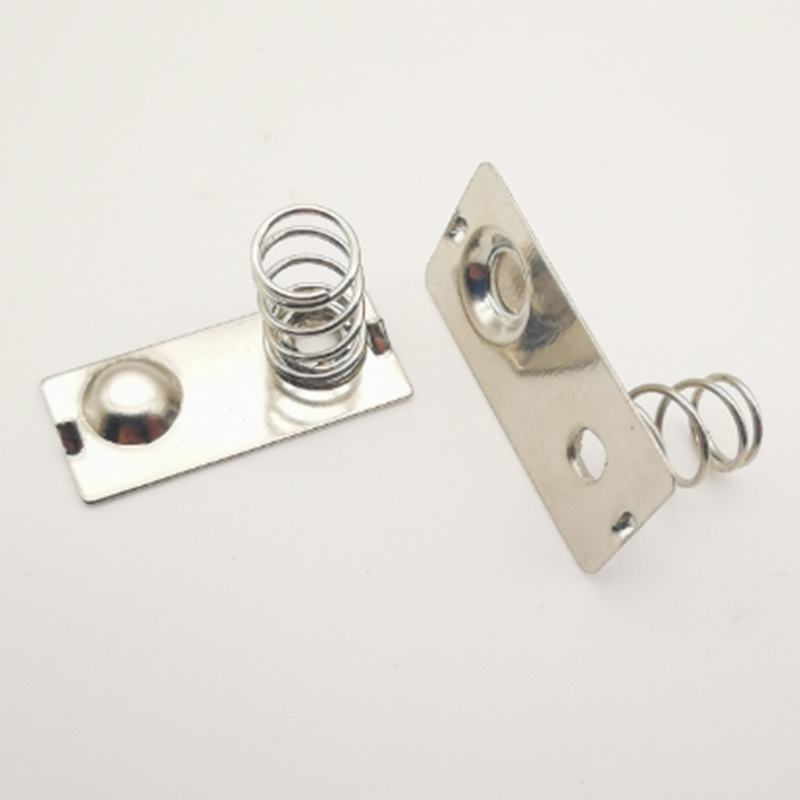

Product detail pictures:

Related Product Guide:

Our commission should be to provide our end users and clients with very best excellent and aggressive portable digital products and solutions for China OEM Progressive Die Cold Stamping Mould – Supporting services for die casting – RAISING-Elec , The product will supply to all over the world, such as: Sydney, Guatemala, Croatia, Looking forward, we will keep pace with the times, continuing to create new products. With our strong research team, advanced production facilities, scientific management and top services, we will supply high quality products to our customers worldwide. We sincerely invite you to be our business partners for mutual benefits.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.