China OEM Custom Steel Parts Supplier – OEM ODM fastener customization service – RAISING-Elec

China OEM Custom Steel Parts Supplier – OEM ODM fastener customization service – RAISING-Elec Detail:

Bolt connecting for steel structure is a connection method that connects more than two steel structure parts or components into one by bolts. Bolt connection is the simplest connection method in component pre assembly and structural installation.

Bolted connection is the earliest used in metal structure installation. In the late 1930s, bolt connection was gradually replaced by rivet connection, which was only used as a temporary fixing measure in component assembly. High strength bolt connection method appeared in the 1950s. High strength bolts are made of medium carbon steel or medium carbon alloy steel, and their strength is 2 ~ 3 times higher than that of ordinary bolts. High strength bolt connection has the advantages of convenient construction, safety and reliability. It has been applied in the manufacturing and installation of steel structures in some metallurgical plants since the 1960s.

Bolt specifications commonly used in steel structures include M12, M16, M20, M24 and M30. M is the bolt symbol and the number is the nominal diameter.

Bolts are divided into 10 grades according to performance grades: 3.6, 4.6, 4.8, 5.6, 5.8, 6.8, 8.8, 9.8, 10.9 and 12.9. Bolts above grade 8.8 are made of low-carbon alloy steel or medium carbon steel and are generally referred to as high-strength bolts after heat treatment (quenching and tempering), and bolts below grade 8.8 (excluding grade 8.8, refined ordinary bolts also include grade 8.8) are generally referred to as ordinary bolts. The following table shows the performance grade and mechanical properties of bolts.

● Wire-EDM : 6 Sets

● Brand: Seibu & Sodick

● Capability: Roughness Ra<0.12 / Tolerance +/-0.001mm

● Profile Grinder: 2 Sets

● Brand: WAIDA

● Capability: Roughness <0.05 / Tolerance +/-0.001

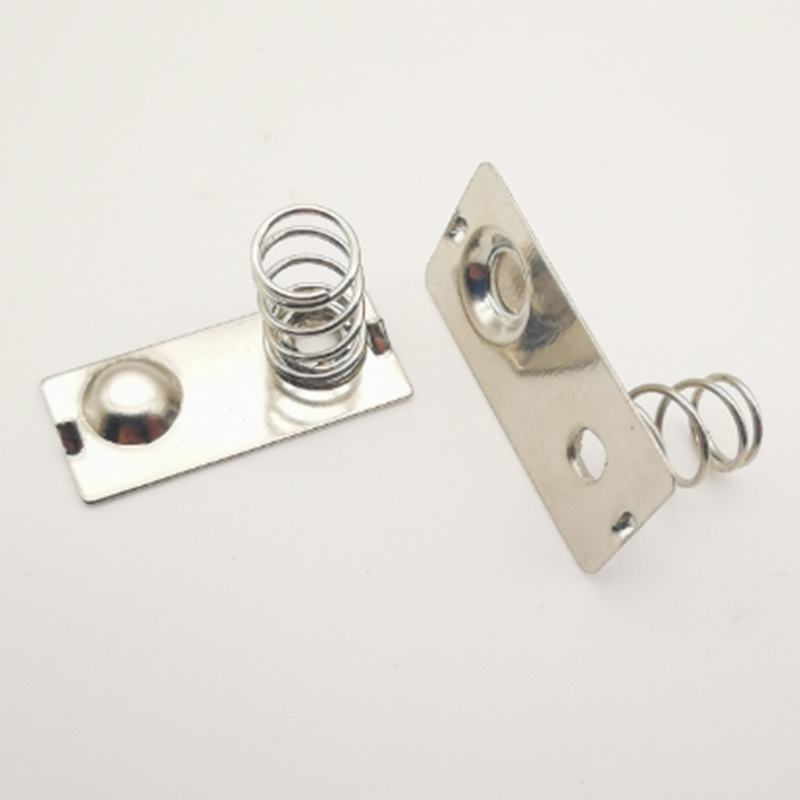

Product detail pictures:

Related Product Guide:

With sophisticated technologies and facilities, strict top quality handle, reasonable value, exceptional support and close co-operation with clients, we are devoted to furnishing the ideal worth for our clients for China OEM Custom Steel Parts Supplier – OEM ODM fastener customization service – RAISING-Elec , The product will supply to all over the world, such as: Mexico, Algeria, Mexico, Our company always concentrate on the development of the international market. We have a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.