China OEM Custom Cnc Precision Machining Service – CNC machining for small parts – RAISING-Elec

China OEM Custom Cnc Precision Machining Service – CNC machining for small parts – RAISING-Elec Detail:

The machining industry includes: filament power winding, laser cutting, heavy processing, metal bonding, metal drawing, plasma cutting, precision welding, roll forming, sheet metal bending, die forging, water jet cutting, precision welding, etc. Broadly speaking, machining refers to the process of manufacturing products by mechanical means; It narrowly refers to the process of manufacturing and processing parts with lathes, milling machines, drilling machines, grinding machines, stamping machines, die casting machines and other mechanical equipment.

The machines required for processing are digital display milling machine, digital display forming grinder, digital display lathe, EDM machine, grinder, machining center, laser welding, medium wire walking, etc., which can carry out turning, milling, planing, grinding and CNC processing of precision parts. Such machines are good at turning, milling, planing, grinding and CNC processing of precision parts, and can process various irregular mechanical parts, with a machining accuracy of 2 μ m. You can also select the appropriate processing technology and production and processing equipment according to the different accuracy requirements of the drawing.

CNC, also known as computer gong or CNC machining, is actually a name in Hong Kong. Later, it was introduced into China. In fact, it is a CNC milling machine. In Guangzhou, Jiangsu, Zhejiang and Shanghai, there is a kind of machining called “CNC machining center”. It is a new machining technology. Its main work is to prepare machining programs, that is, to change the original manual work into computer programming. Of course, you need experience in manual processing.

① The number of tooling is greatly reduced, and complex tooling is not required for machining parts with complex shape. If you want to change the shape and size of parts, you only need to modify the part processing program, which is suitable for new product development and modification.

② It has stable processing quality, high processing precision and high repetition precision, and can meet the processing requirements of aircraft.

③ In the case of multi variety and small batch production, the production efficiency is high, which can reduce the time of production preparation, machine tool adjustment and process inspection, and reduce the cutting time due to the use of the best cutting amount.

④ It can process complex surfaces that are difficult to be processed by conventional methods, and even process some unobservable machining parts.

1. Precision machining.

2. Precision equipment parts processing.

3. Processing of non-standard spare parts.

4. Machining of precision special-shaped parts.

5. Hardware and mechanical parts processing.

6. Surface treatment of various mechanical parts.

● Wire-EDM : 6 Sets

● Brand: Seibu & Sodick

● Capability: Roughness Ra<0.12 / Tolerance +/-0.001mm

● Profile Grinder: 2 Sets

● Brand: WAIDA

● Capability: Roughness <0.05 / Tolerance +/-0.001

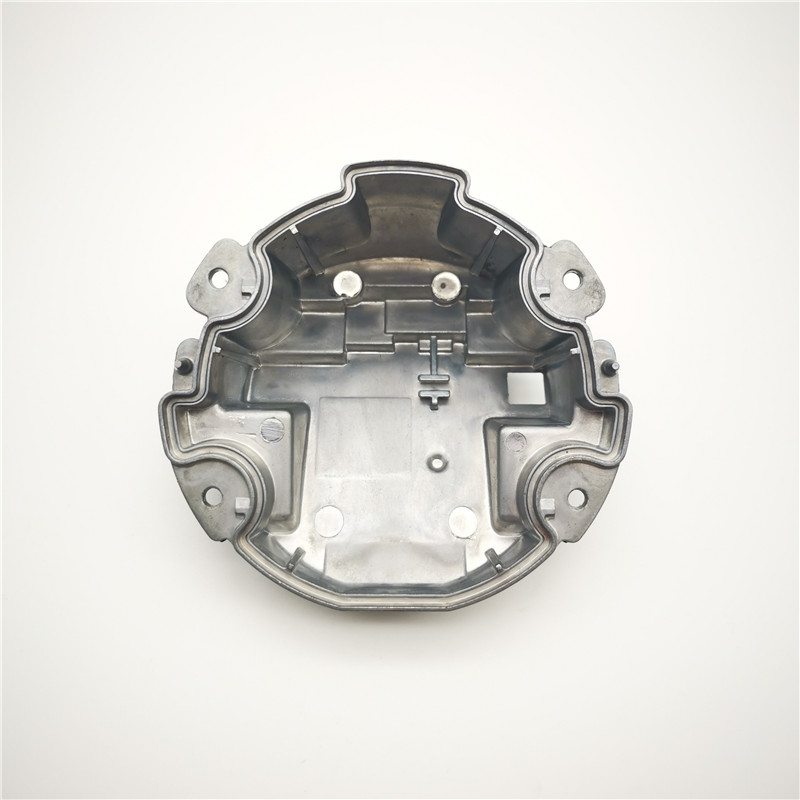

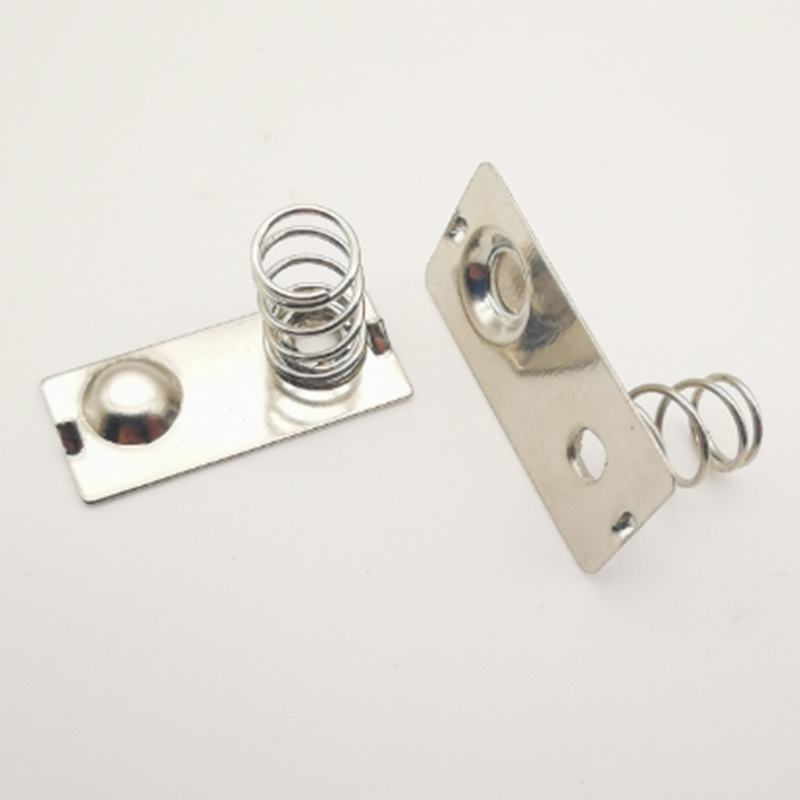

Product detail pictures:

Related Product Guide:

Quality comes first; service is foremost; business is cooperation" is our business philosophy which is constantly observed and pursued by our company for China OEM Custom Cnc Precision Machining Service – CNC machining for small parts – RAISING-Elec , The product will supply to all over the world, such as: Barbados, kazan, Bhutan, Item have passed by means of the national qualified certification and been well received in our main industry. Our expert engineering team will often be ready to serve you for consultation and feedback. We are able to also deliver you with cost-free samples to meet your specifications. Ideal efforts will probably be produced to provide you the most beneficial service and solutions. Should you be interested in our company and solutions, please make contact with us by sending us emails or call us straight away. To be able to know our solutions and enterprise. ar more, you'll be able to come to our factory to see it. We'll constantly welcome guests from all over the world to our firm. o build business enterprise. elations with us. Please feel absolutely free to speak to us for organization. nd we believe we will share the best trading practical experience with all our merchants.

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.