Sheet Metal Stamping Manufacturer – OEM ODM metal stamping customization – RAISING-Elec

Sheet Metal Stamping Manufacturer – OEM ODM metal stamping customization – RAISING-Elec Detail:

General requirements for appearance of metal precision stamping parts

Most of the products we use now have been tested. Only qualified products can be delivered from the warehouse, and the products processed by metal stamping parts are the same. So what kind of metal stamping parts can be considered qualified? If the metal precision stamping parts are scrapped soon after use, is such a product qualified? The following Xiaobian will explain to you how the processing technology of metal stamping parts is qualified.

1. The basic performance of products processed by metal precision stamping parts must be met, and the assembly and repair of products need to be fast, convenient and easy.

2. The products processed by metal precision stamping parts have simple shape and reasonable structure, which can be conducive to the processing of molds, that is, complete the processing of the whole parts with the least time and the simplest process, quickly realize mechanized and automatic production and improve production efficiency.

3. Hardware precision stamping parts should be processed by using the existing material equipment, process equipment and process flow as much as possible, and the service life of stamping die should be guaranteed.

4. The products processed by metal precision stamping parts can improve the utilization rate of metal materials, reduce the variety and specification of materials, and reduce the consumption of materials. It is possible to achieve no waste and less waste blanking in the processing process.

5. It can reduce the dimensional accuracy grade and surface roughness under the condition of ensuring the normal use of hardware precision stamping parts, which is conducive to the exchange of products and reduce scrap.

Metal precision stamping parts are widely used in various fields of our life, including some electronic devices, auto parts, decorative materials and so on. If we don’t pay attention to the production of metal stamping parts, some unnecessary things may occur. What problems should we pay attention to in the production process? Let’s answer it.

● Wire-EDM : 6 Sets

● Brand: Seibu & Sodick

● Capability: Roughness Ra<0.12 / Tolerance +/-0.001mm

● Profile Grinder: 2 Sets

● Brand: WAIDA

● Capability: Roughness <0.05 / Tolerance +/-0.001

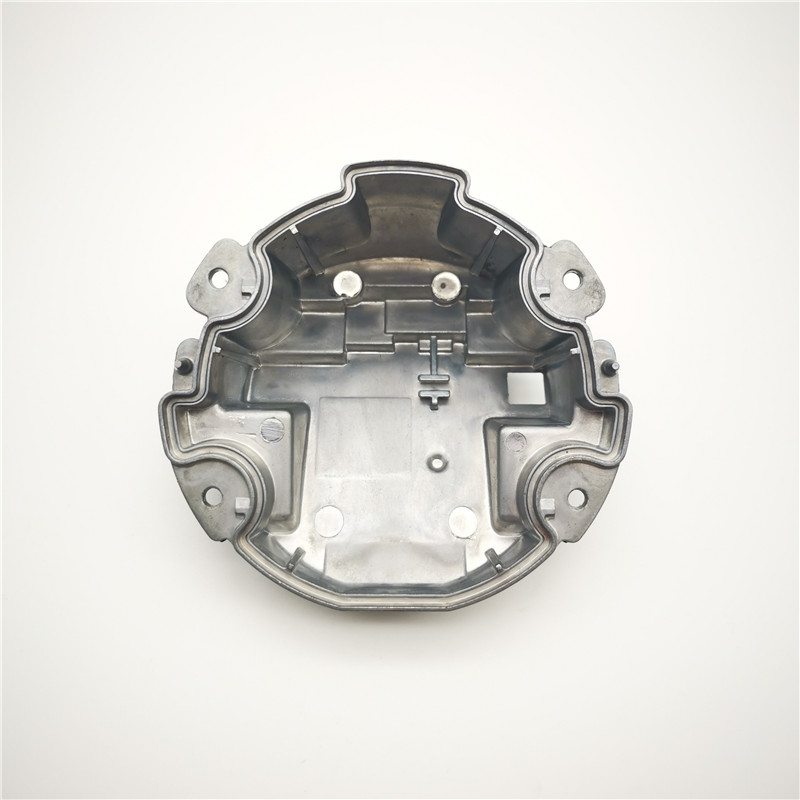

Product detail pictures:

Related Product Guide:

As a way to finest meet up with client's wants, all of our operations are strictly performed in line with our motto "High Quality, Aggressive Price, Fast Service" for Sheet Metal Stamping Manufacturer – OEM ODM metal stamping customization – RAISING-Elec , The product will supply to all over the world, such as: Guatemala, Rio de Janeiro, San Francisco, Our company has a skillful sales team, strong economic foundation, great technical force, advanced equipment, complete testing means, and excellent after-sales services. Our items have beautiful appearance, fine workmanship and superior quality and win the unanimous approvals of the customers all over the world.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!