ODM Precision Cnc Machining Parts Manufacturer – High Precision CNC Machining manufacture – RAISING-Elec

ODM Precision Cnc Machining Parts Manufacturer – High Precision CNC Machining manufacture – RAISING-Elec Detail:

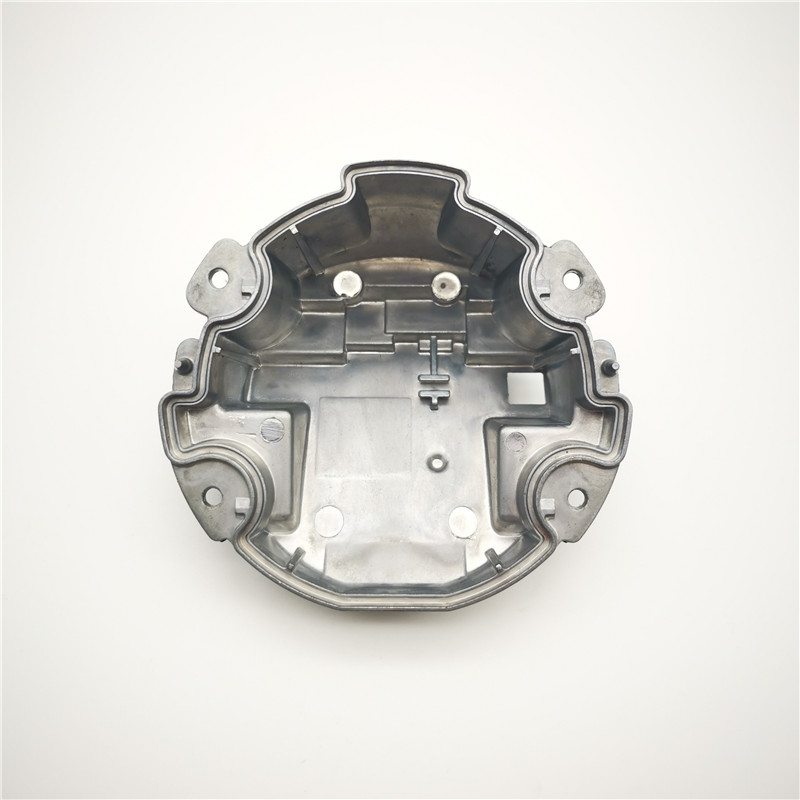

Material: 20# steel 5052 aluminum

Processing equipment: precision milling and turning

Accuracy requirement: 0.01mm Parallelism: 0.01mm concentricity: 0.01mm

Surface treatment: chrome plating, oxidation and blackening

Machining scope of Raising:

1. Precision machining.

2. Precision equipment parts processing.

3. Processing of non-standard spare parts.

4. Machining of precision special-shaped parts.

5. Hardware and mechanical parts processing.

6. Surface treatment of various mechanical parts.

In the mechanical processing industry, CNC processing plant equipment has high-speed and processing capacity, but can it play a role. It also depends on the choice of tools, because tools are the basic, effective and active factor to realize high-speed and cutting. According to the research of many famous tool manufacturers in the world, it is understood that the average tool cost and production cost in developed countries and other relevant data, it is found that reducing the tool cost by 30% can reduce the single piece production cost by 1%; Increase the tool life by 50% and reduce the production cost by 1%; Increasing the processing efficiency by 20% can reduce the production cost by 15%. This can fully explain that using modern cutting technology, selecting high-speed and cutting tools, giving full play to the performance and efficiency of machine tools, and realizing high-speed and cutting is the correct way to organize production rate and reduce production cost in the flexible production line of CNC processing equipment.

● Wire-EDM : 6 Sets

● Brand: Seibu & Sodick

● Capability: Roughness Ra<0.12 / Tolerance +/-0.001mm

● Profile Grinder: 2 Sets

● Brand: WAIDA

● Capability: Roughness <0.05 / Tolerance +/-0.001

Product detail pictures:

Related Product Guide:

Our firm since its inception, normally regards item top quality as company life, constantly make improvements to generation technology, improve product excellent and repeatedly strengthen organization total good quality management, in strict accordance with the national standard ISO 9001:2000 for ODM Precision Cnc Machining Parts Manufacturer – High Precision CNC Machining manufacture – RAISING-Elec , The product will supply to all over the world, such as: Moldova, Russia, Bandung, Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our products and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!